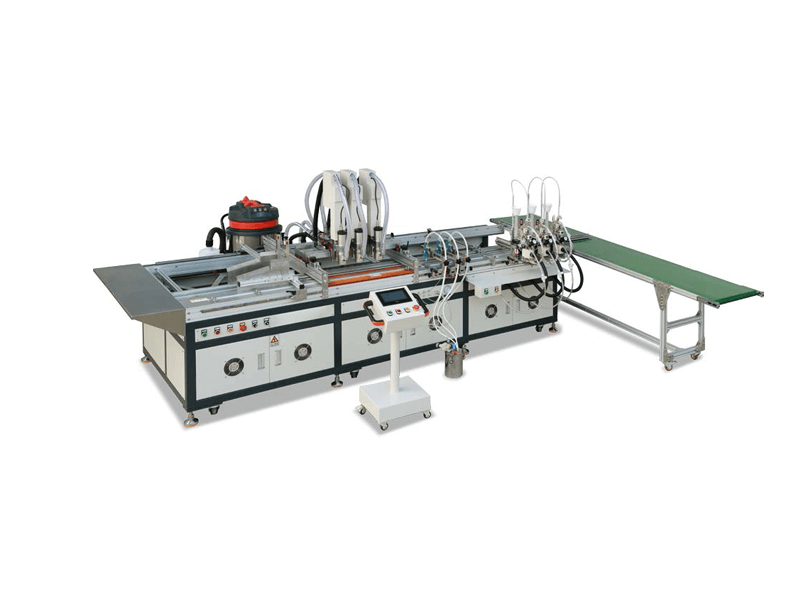

The machine is applied to make the book style rigid boxes. It has the functions of automatically feeding the material, drilling, gluing, sticking the magnets/iron discs.

36

boxs / min

In place of the hand working, it is efficient, stable and small footprint which is widely accepted by customers.

1. Auto non-stop feeder: It adopts the bottom drawn feeder. The material(cardboard/case) is fed from the bottom of stacker(Max.200mm).

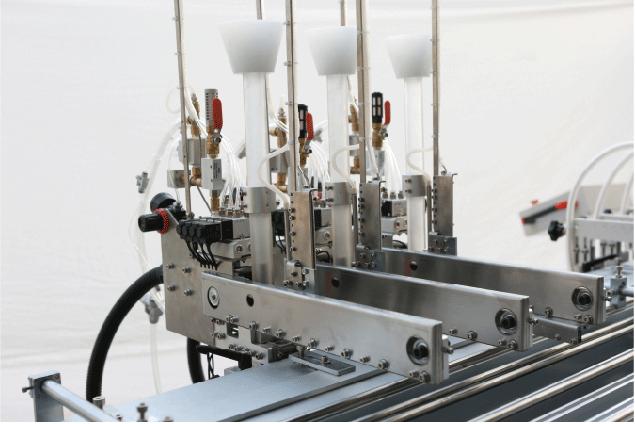

2. Auto drilling: the depth of hole can be adjusted. And the waste of material is automatically removed and collected by vacuum cleaner. It avoids the problem of uneven hole by hand working .

3. Auto gluing: The volume and position of gluing is adjustable according to the products, which efficiently solve the problem of glue squeeze -out and positioning. Iron disc has the optional device of Vibrating plate which can feed the discs automatically.

4. Auto sticking: It can stick 1-3pcs magnets/iron discs. The position, speed, pressure and program are adjustable.

| Model | ZR600 |

| Cardboard size | Max. 900*500mm Min. 120*90mm |

| Stacker Height | 20cm |

| Throat Depth | 12-110mm |

| Cardboard thickness | 1-3mm |

| Magnet diameter | 8-20mm |

| Magnet Qty | 1-3mm |

| Gap distance | 90-420mm |

| Glue tank capacity | 1L |

| Speed | ≤36pcs/min |

| Air supply | 0.6Mpa |

| Power | 5Kw, 220V/1P, 50Hz |

| Machine dimension | 3600*2000*1600mm |

| Machine weight | 780KG |

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.