Patented rear suction paper feeder with independent servo control for paper feeding, simple and easy to maintain.

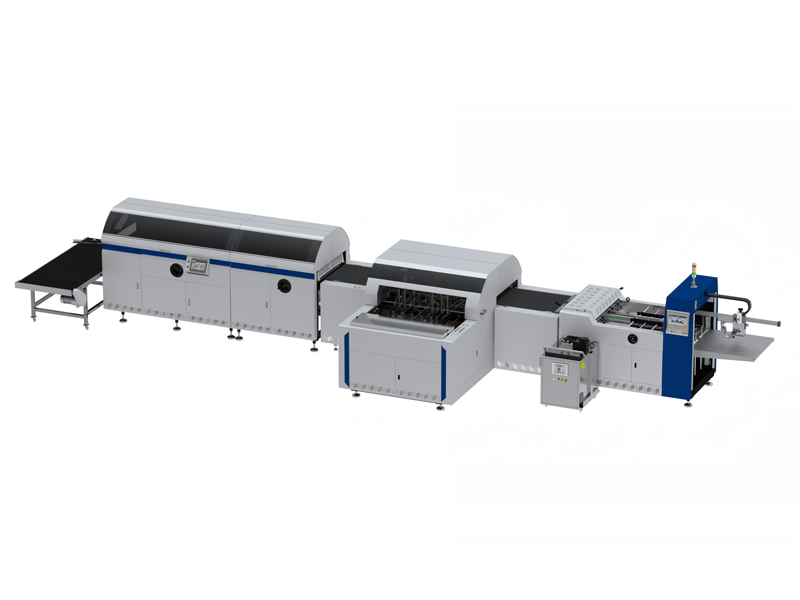

CM450B Automatic Case Maker (Photoelectric Positioning)

The high-stability workhorse for long-run production. The CM450B is designed for high-volume, continuous manufacturing of standard-sized covers.

It uses a reliable Photoelectric Positioning system and a robust standard straight-edge folding structure (Front Tucking + Straight Plate), ensuring maximum stability and efficiency for dedicated, non-irregular jobs.

Max. Size: (e.g., 450 x 800 mm)

Core Tech: Photoelectric (Optical) Positioning.

Key Feature: Optimized for long-run, standard straight-edge covers.

Benefit: Extremely reliable and cost-effective for mass production of standard book covers.

≤38

boxs / min

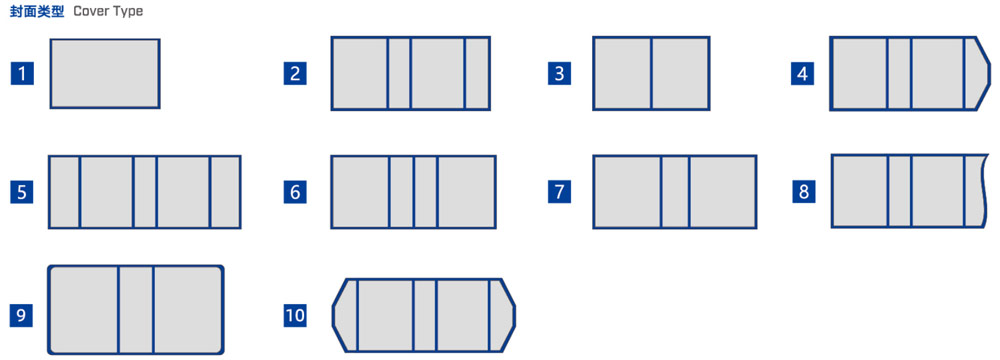

The most common, standard rectangular covers. For example, a regular hardcover notebook; a standard hardcover novel case; or the flat lid for a shoe box.

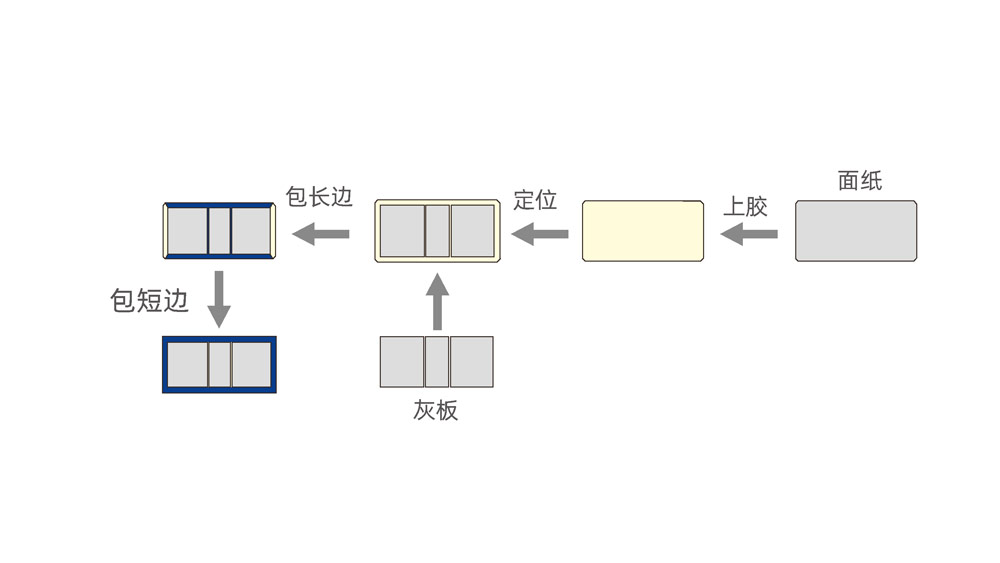

It can automatically feed and glue paper, delivery and position cardboard, and fold four sides in one process; there are features of accurate and quick positioning, and beautiful finished products etc. It is used to make hardcovers, notebook covers, desk calendars, hanging calendars, book-type boxes, fles and irregular covers etc.

Patented rear suction paper feeder with independent servo control for paper feeding, simple and easy to maintain.

Pneumatic paper pressure wheel and ultrasonic double-sheet detection device ensure smooth paper feeding and effectively prevent double sheets.

Photoelectric tracking detection servo deviation correction to ensure positioning accuracytt.

![Trimming Of Motor Parts[Model A]](https://meiguo-oss.oss-us-west-1.aliyuncs.com/zhengrun_new/upload/1c/202510/CM450B&600A-Product-Advantage-4.jpg)

Trimming controlled by stepper motor, adjustable,faster and more accurate.

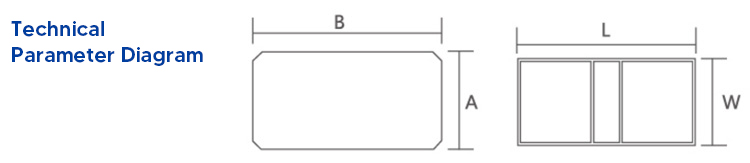

| Model | CM450B |

| Paper Size(A×B) | Min.110×210mm |

| Max.480×830mm | |

| Case Size(W×L) | Min.80×180mm |

| Max.450×800mm | |

| Paper Thickness | 100~300g/m² |

| Cardboard Thickness | 1-4mm |

| Spine Width(S) | ≥7mm |

| Folding Size | 10-18mm |

| Cardboard Qty | 6pcs |

| Precision | ±0.5mm |

| Speed | ≤38sheets/min |

| Motor Power | 12kw/380v 3phase |

| Electric Heating Power | 12kw |

| Air Supply | 30L/min 0.6Mpa |

| Machine Dimension | L8200×W2100×H1700mm |

| Machine Weight | 3500kg |

| Cover Type | 1/2/3/5/6/7 |

1.The max and mini sizes of the covers are subjected to the size and the quality of the paper.

2.The speed of the machine depends on the sizes of the covers.

3.We don't provide air compressor.

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.