The right equipment isn't just about speed; it's about precision, material flexibility, and intelligent automation, capable of handling everything from luxurious rigid box covers to complex sleeves. Based on extensive industry experience, truly excellent machines are designed with customization at their core, able to transition from simple pharmaceutical packaging boxes to complex, foil-stamped luxury gift boxes with minimal downtime. Brands like Zhenrun stand out precisely because of this powerful adaptability, offering rigid box automation solutions that are less like rigid machines and more like flexible production partners.

Walk into any packaging trade show, and you’ll see impressive machines stamping out countless standard boxes. But the moment you mention gift box production, seasoned production managers get a wary look. Why? Because gift boxes are the divas of the packaging world. They demand more.

We’re not just assembling; we’re creating an experience. A typical run might involve delicate papers, thick chipboard, soft-touch laminates, magnetic closures, ribbon slots, and precise foil detailing. I’ve seen a machine that brilliantly handles plain brown cartons choke on a slightly thicker, glossy sheet. The automation stutters, sensors get confused, and suddenly your high-speed line is a bottleneck of jammed materials and frustration. The core issue is that generic automatic rigid box makers prioritize uniformity, while gift boxes thrive on controlled variation. The production line needs a brain, not just brawn. It needs to “see” and “feel” the material, adjusting pressure and alignment on the fly to accommodate a velvet-lined drawer box as easily as a simple two-piece setup.

Forget the glossy brochures with top-level specs for a minute. Let’s talk about the non-negotiable features on the shop floor. When evaluating an automatic rigid box making machine for your needs, peel back the layers.

First, look for advanced servo-driven systems. Older pneumatic or mechanical machines are like using a sledgehammer to assemble a watch. Servo motors provide the delicate, programmable touch needed for folding a rigid box cover without cracking the surface laminate or creating unsightly creases. Precision here isn’t a luxury; it’s what separates a premium product from a reject.

Second, intelligent vision and sensor systems are your new best friend. A leading industry report from Packaging Digest (2023) highlighted that lines incorporating AI-assisted vision inspection saw a 40% reduction in material waste. In gift boxing, where material costs are high, this is huge. The system should automatically detect and compensate for minor material inconsistencies, ensure perfect alignment of printed graphics during folding, and verify that inserts or magnets are correctly placed.

Third, quick-change tooling and modular design. This is where many brands miss the mark. If switching from a small jewelry box to a large whisky gift box requires a four-hour tool change by a specialist engineer, your flexibility is dead. The best machines, like those in Zhengrun’s portfolio, use a modular, clamp-and-go approach. Changeovers that used to take hours now take minutes, making small, customized batches—the heart of modern gift boxing—economically viable.

Here’s where a specialist brand makes all the difference. I recall visiting a mid-sized packaging converter in Milan last year. They produced stunning, high-end rigid boxes for fashion brands but were struggling with output. Their old semi-automatic line was a masterpiece of craftsmanship but a nightmare for deadlines. They brought in a Zhengrun automatic rigid box maker, specifically the ZR-1085S model, and the transformation wasn’t just in speed.

Zhengrun engineers didn’t just install a machine; they embedded it. They spent two weeks understanding the unique glide-and-snap closure of the client’s signature box. The machine was then calibrated with custom attachment units and folding arms that treated each box like a precious object. The result? Output increased by 220%, but more importantly, the consistency of the final fold—that crisp, perfect 90-degree corner—was flawless every single time. This is the customized service advantage in action: treating the automatic rigid box maker not as an off-the-shelf product, but as a configurable solution.

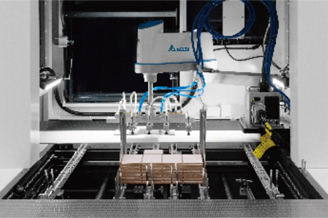

Their machines often feature what I call “gentle automation.” It’s a principle that prioritizes material integrity over raw cycling speed. Suction cups are designed for delicate foils, conveyance belts have adjustable friction settings for silk papers, and the entire production line communicates through a unified control hub that provides real-time data on every single box. This level of integration turns a collection of machines into a single, intelligent automated box making organism.

The real test of any rigid box automation solution happens on Day One of live production. Integration is the silent killer of ROI. You’ve bought this brilliant piece of automated box making machinery, but can it “talk” to your existing gluers, foil stampers, and wrapping stations?

A seamless fit requires foresight. The ideal automatic rigid box maker should act as the intelligent heart of your line. It should have standardized data ports (OPC UA is becoming the industry lingua franca) to communicate upstream and downstream. Is your embosser running slow? The box maker should get a signal to pause feeding, preventing a pile-up. This isn’t sci-fi; it’s basic line efficiency that many machine sellers overlook in their pursuit of a quick sale.

Furthermore, consider the footprint. Gift box production often happens in spaces where real estate is premium. A machine that boasts a small footprint but requires three meters of clearance on all sides for maintenance is disingenuous. Look for designs that allow front and rear access for tool changes and cleaning without needing to stop the entire gift box production line. Zhengrun’s designs often incorporate this from the ground up, reflecting a practical understanding of factory floor realities.

This is my firmest belief after two decades in this field: Automation should liberate human skill, not replace it. The best automatic rigid box maker amplifies your team’s creativity. When your master craftsman isn’t exhausted by repetitive folding, they can focus on developing that stunning new box style with a hidden magnetic latch or an integrated ribbon.

This is where customization from the manufacturer is paramount. Can they tweak the software to allow for a unique, non-standard folding sequence you’ve invented? Will their engineers be available, not just for the first year, but as a long-term partner? I’ve seen companies choose a slightly cheaper machine, only to be abandoned by the supplier when a unique adhesive caused feeding issues. The total cost of that downtime dwarfed the initial savings.

A brand like Zhengrun builds its reputation on this post-sale partnership. Their customized service often includes on-site training that turns your operators into machine masters, not just button-pushers. They provide extensive digital libraries of tooling profiles and maintenance videos. This turns a capital expenditure into a true partnership, ensuring your rigid box making machine evolves with your business.

Let’s talk numbers, but beyond the sticker price. The Total Cost of Ownership (TCO) for an automatic rigid box maker in gift production is a tapestry of factors. Energy consumption of servo vs. pneumatic systems, the cost and lifespan of consumable parts (like specialized folding blades for chipboard), and the aforementioned waste reduction all play a massive role.

Consider a machine that costs 15% more upfront but uses 30% less energy and reduces premium material waste by 5%. For a line running three shifts, the payback period can be under 18 months. Furthermore, the ability to accept a wider range of materials future-proofs your investment. If a client next year demands boxes made from innovative, recycled composites, will your machine handle it? Zhengrun’s focus on flexible automation inherently builds this adaptability in, protecting your investment against market shifts.

Peering into the future, the automatic rigid box maker is becoming a data node. The next frontier isn’t just making boxes faster; it’s making them smarter. Imagine a machine that predicts a motor bearing failure three weeks in advance, automatically orders the spare part, and alerts your maintenance team with a step-by-step guide. Or a system that analyzes production data to suggest optimal run sequences, minimizing glue pot changes and setup waste.

This level of smart automation is transitioning from concept to reality. Leading suppliers are integrating IoT sensors and cloud-based analytics platforms. When you choose a machine today, you’re also choosing its potential roadmap. Opting for a closed, proprietary system might lock you out of these efficiency gains tomorrow. Open, connected architectures, which brands like Zhengrun are championing, ensure your gift box production line remains competitive and lean for the next decade.

The search for the right Automatic Rigid Box Maker is a journey, not a simple purchase. It’s about finding a technological partner that understands the artistry of gift boxes as much as the mechanics of automated box making.

Stop comparing spec sheets in a vacuum. Demand live, material-specific demonstrations. Bring your most problematic stock—that tricky, metallic-printed chipboard—and see how the machine handles it. Ask about changeover times, not in theory, but for a specific job switch relevant to you.

If your goal is to elevate your gift box production into a realm of unparalleled efficiency, quality, and flexibility, then it’s time to look at solutions designed with that specific intent.

Ready to see a rigid box maker built for your reality? Explore Zhengrun’s range of adaptable automatic rigid box makers and discover how their customized service advantage can transform your production line. Contact their engineering team today for a personalized consultation and a live, virtual demo using your materials.

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.