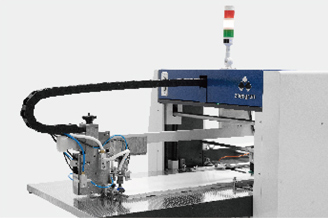

Patented rear suction paper feeder with independent servo control for paper feeding, simple and easy to maintain.

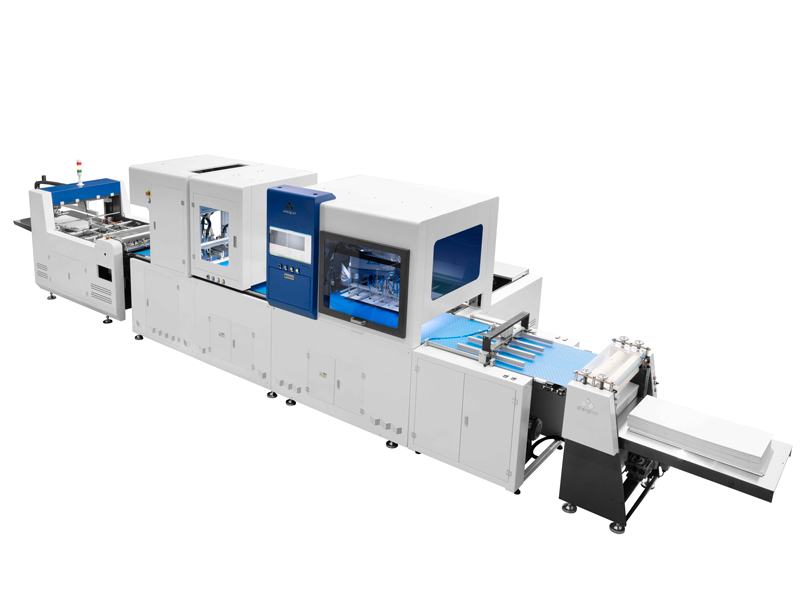

CB600TC Vision Positioning Machine (with magnet and metal plate application)

The all-in-one solution for luxury packaging. This machine combines ultra-high precision vision spotting (CCD) with an integrated automatic magnet and metal plate applicator.

Features one-key adjustment for rapid setup of both functions.

Core Function: Ultra-high precision spotting (± 0.05mm).

Added Value: Automatically inserts magnets & metal plates in one pass.

Benefits: Flawless quality, massive labor savings, and zero errors.

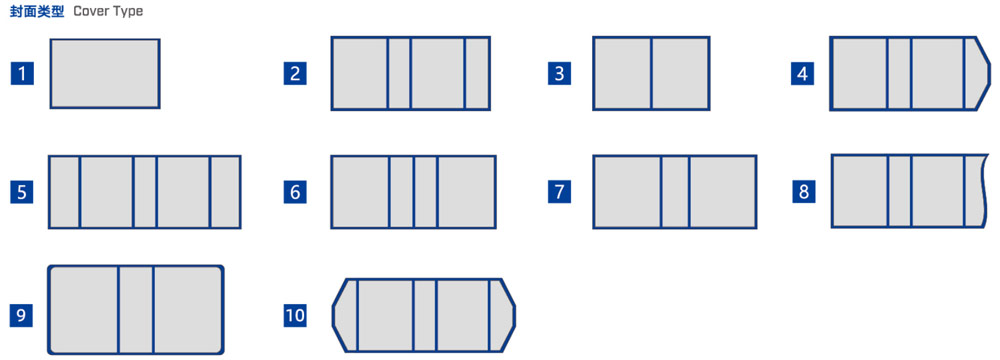

Applications: Essential for magnetic closure boxes, phone boxes, and high-end gift boxes.

≤30

boxs / min

Any box that "snaps" shut. For example, a high-end tea gift box with hidden magnets, or a premium headphone box with an embedded metal plate in the lid.

It can automatically feed and glue paper, delivery and position cardboard, and fold four sides in one process; there are features of accurate and quick positioning, and beautiful finished products etc. It is used to make hardcovers, notebook covers, desk calendars, hanging calendars, book-type boxes, fles and irregular covers etc.

Patented rear suction paper feeder with independent servo control for paper feeding, simple and easy to maintain.

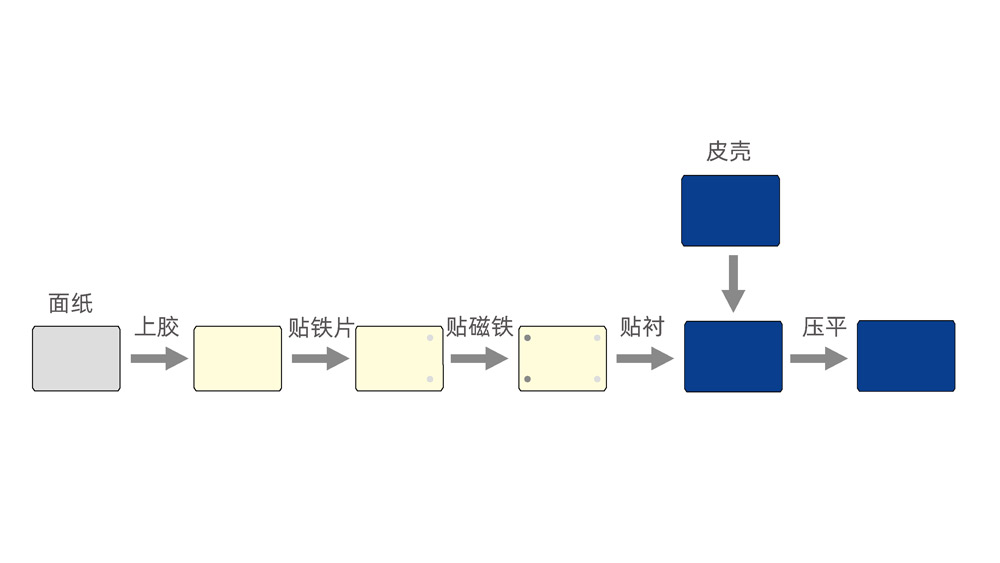

All glue rollers are made of finely ground stainless steel chrome-plated rollers and use line-contact scrapers for greater durability.

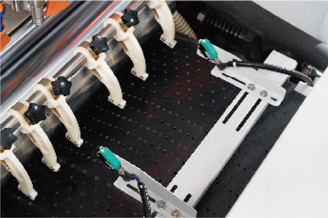

The patch station can automatically position the iron sheet and automatically dispense glue after positioning.

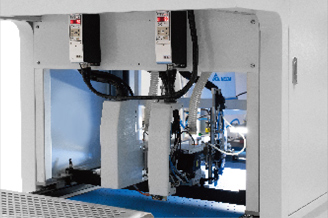

The magnet is installed by the robot, and the robot positions the cardboard with high precision.

| Model | CB600TC |

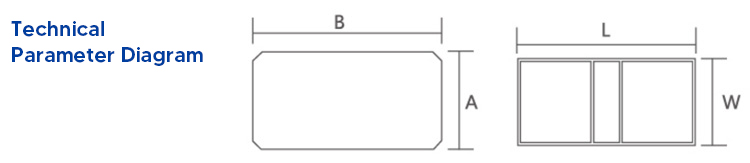

| Paper Size[A×B] | Min.100×200mm Max. 620×1030mm |

| Case Size[W×L] | Min.100×200mm Max. 600×1000mm |

| Paper Thickness | 100~300g/m² |

| Cardboard Thickness | 1-4mm |

| Min.Spine Width[S] | 10mm |

| Cardboard Qty | 5pieces |

| Precision | ±0.05mm |

| Speed | ≤30pcs/min |

| Motor Power | 8kw/380v 3phase |

| Electric Heating Power | 12kw |

| Air Supply | 10L/min 0.6Mpa |

| Machine Weight | 2700kg |

| Machine Dimension | L7150×W2300×H2000mm |

1.The max and mini sizes of the covers are subjected to the size and the quality of the paper.

2.The speed of the machine depends on the sizes of the covers.

3.We don't provide air compressor.

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.