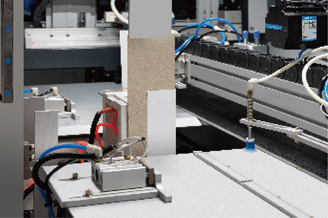

The new cylinder controls the double feeder with front and rear suction and front paper pushing, effectively preventing double sheets, stable operation and higher efficiency

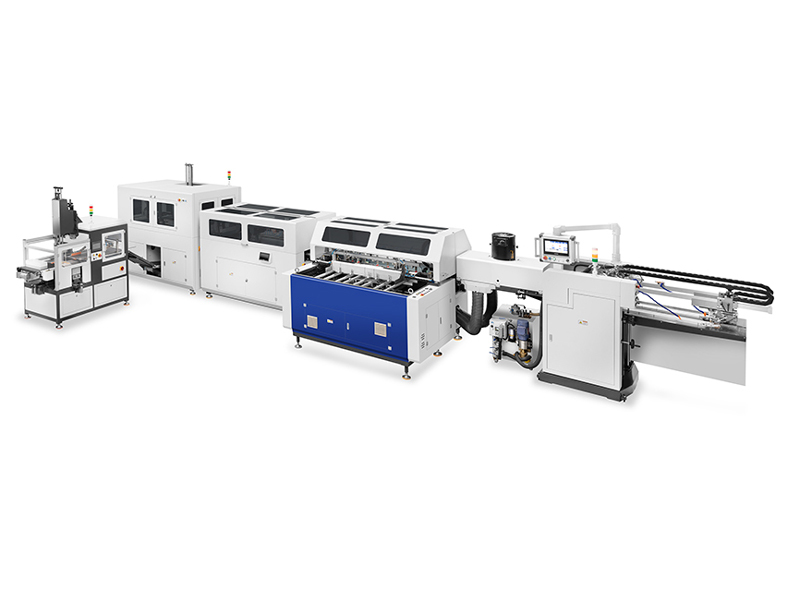

CW380B Automatic Side Frame Forming Machine

The ideal solution for premium rigid box side frames, featuring one-key adjustment for rapid setup and high efficiency

Technology: Advanced Servo Control + PLC system for reliable, high-precision performance.

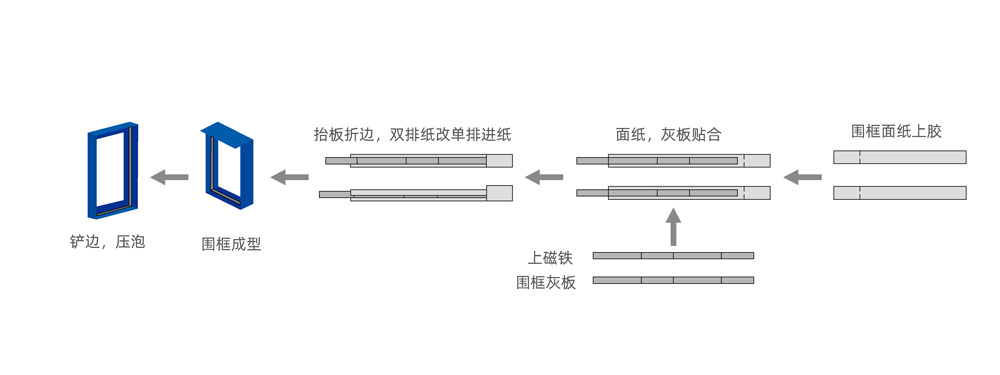

Fully Automatic (All-in-One): Integrates feeding, gluing, positioning, folding, frame forming, and bubble pressing.

Benefits: Replaces manual labor, boosts productivity, and ensures a flawless, high-quality finish.

Applications: Perfect for luxury packaging (cosmetic, wine, mooncake, and tea boxes).

≤25

boxs / min

The rigid inner frame inside an iPhone box; the thick, supportive inner wall for a high-end wine box or mooncake box.

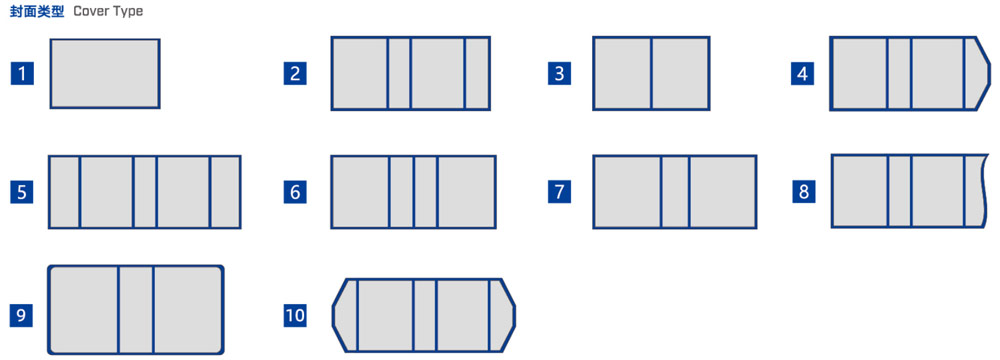

It can automatically feed and glue paper, delivery and position cardboard, and fold four sides in one process; there are features of accurate and quick positioning, and beautiful finished products etc. It is used to make hardcovers, notebook covers, desk calendars, hanging calendars, book-type boxes, fles and irregular covers etc.

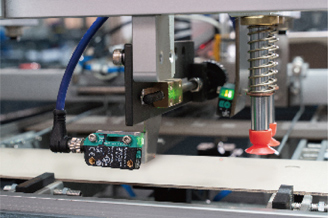

The new cylinder controls the double feeder with front and rear suction and front paper pushing, effectively preventing double sheets, stable operation and higher efficiency

Photoelectric tracking detection and servo correction to ensure positioning accuracy.

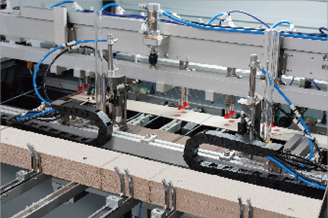

The non-stop stacking device can realize non-stop transportation and ensure the high-speed operation of the machine.

Servo controlled molding ensures efficient and stable frame molding.

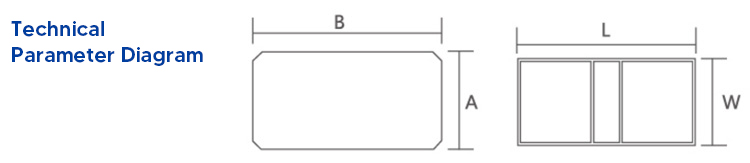

| Model | Dual Paper Feed Mode (Bonding Width of C and B < 230) | Single Paper Feed Mode |

| Paper Size[A×B] | Min.530×50mm Max.1200×C C<200mm | Min.530×50mm Max.1200×320mm |

| Gray board size | Min.520×50mm Max.1200×B B<200mm | Min.520×50mm Max.1200×200mm |

| Frame molding | Min.200×60×50mm Max.L≤400mm,W≤300mm,L+W≤600mm | Min200×60×50mm Max.L≤400mm,W≤300mm,L+W≤600mm |

| Paper Thickness | 100-400g/m² | 100-400g/m² |

| Cardboard Thickness | 0.8~3mm | 0.8~3mm |

| Paper Stacking Height | 550mm | 550mm |

| Folding size (R) | 15-120mm | 15-120mm |

| Cutting Accuracy | ±0.05mm | ±0.05mm |

| Speed | ≤25pcs/min | ≤20pcs/min |

| Power | 20kw/380v 3phase | 20kw/380v 3phase |

| Electric Heating Power | 12kw | 12kw |

| Air supply | 60L/min 0.6Mpa | 55L/min 0.6Mpa |

| Machine dimension | L9400×W2265×H2200mm | L9400×W2265×H2200mm |

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.