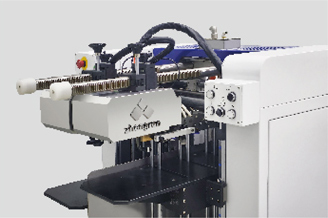

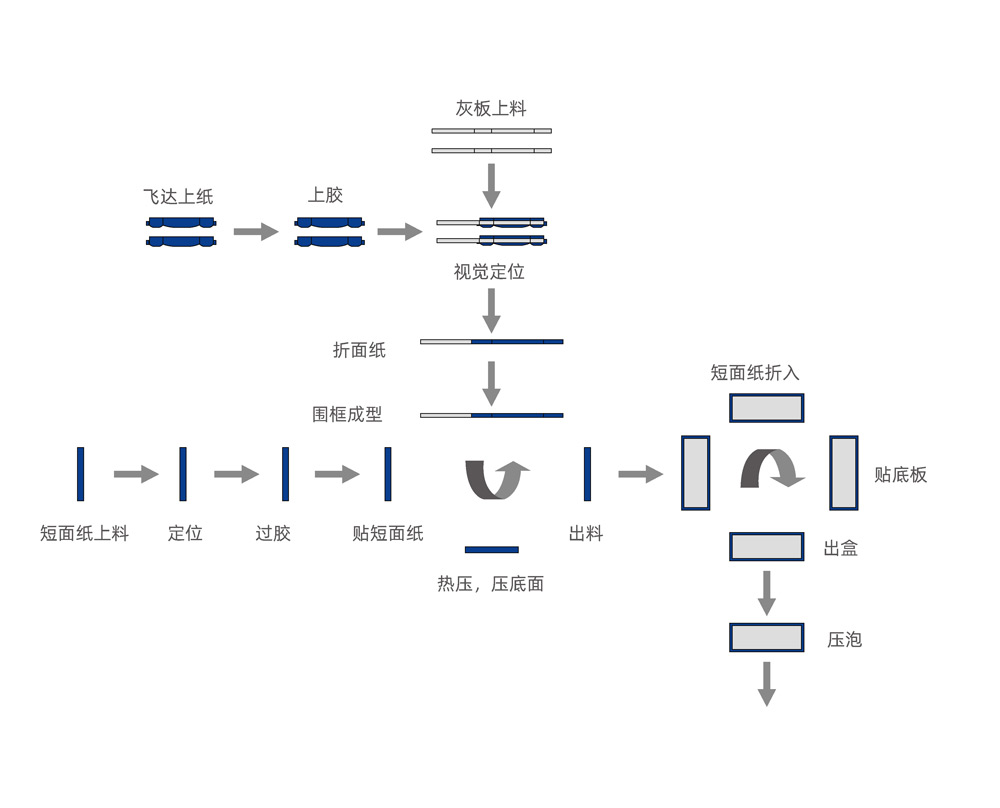

The newly designed double-row servo-controlled paper feeder has higher production efficiency and adopts rear suction and front paper pushing to effectively prevent double sheets and ensure stable operation.

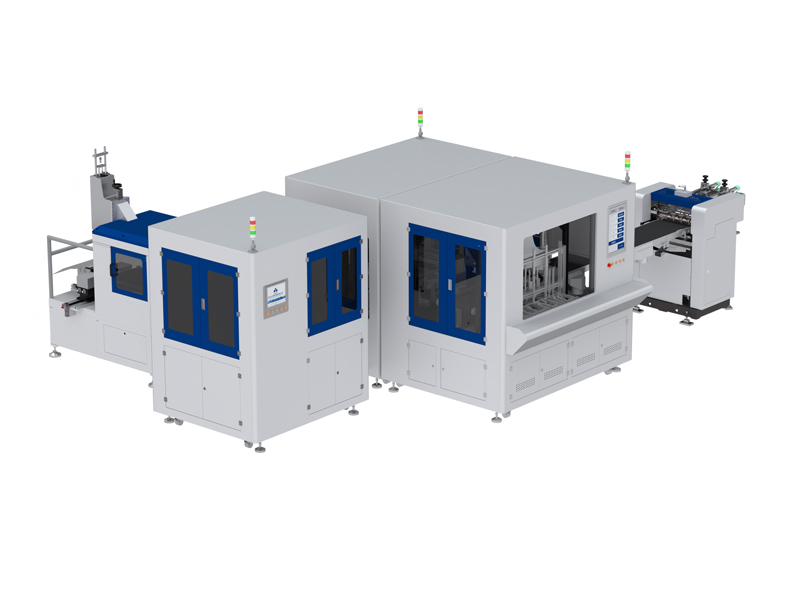

CW320A Fully Automatic Cigarette Box Inner Frame Machine

A specialized, high-speed solution for cigarette box inner frames, now featuring one-key adjustment for rapid setup and maximum efficiency

Key Feature: One-key adjustment via HMI touch screen.

Benefits: Fully automatic, high-precision forming. Saves labor and boosts productivity.

Control: (Assuming) Advanced PLC + Servo system ensures reliable, high-speed performance.

Application: Ideal for cigarette box inner frames and other premium small rigid boxes.

≤25

boxs / min

The inner cardboard frame found inside a hard-pack cigarette box.

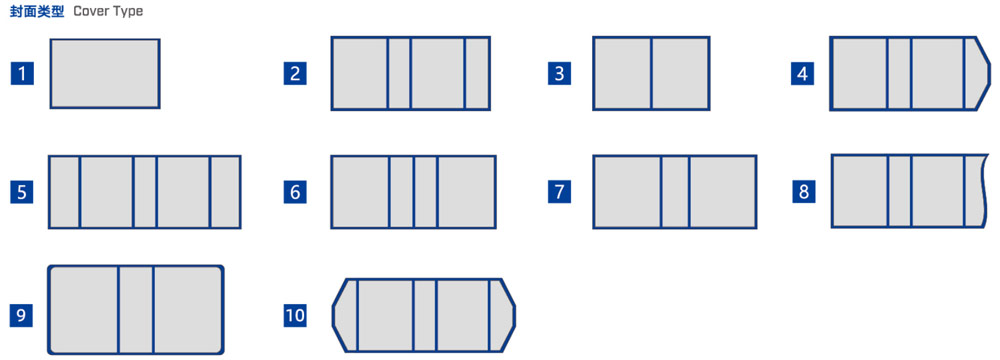

It can automatically feed and glue paper, delivery and position cardboard, and fold four sides in one process; there are features of accurate and quick positioning, and beautiful finished products etc. It is used to make hardcovers, notebook covers, desk calendars, hanging calendars, book-type boxes, fles and irregular covers etc.

The newly designed double-row servo-controlled paper feeder has higher production efficiency and adopts rear suction and front paper pushing to effectively prevent double sheets and ensure stable operation.

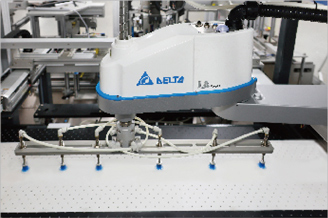

Image positioning and the robot arm dust absorption plate are bonded to the surface paper to achieve high-precision positioning.

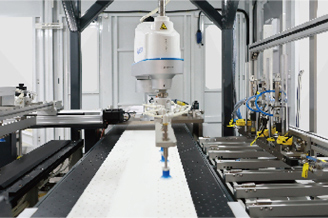

Full servo folding mechanism, the folding quality is more stable and the machine adjustment is more convenient.

The servo-controlled high-precision cam divider works in conjunction with pneumatic control to complete the enclosure product, making the product production quality more stable and faster.

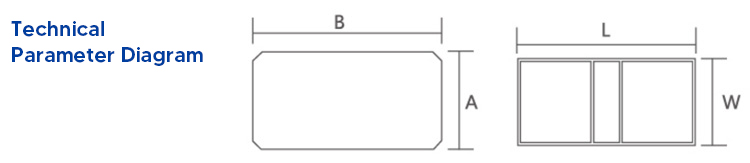

| Model | CW320A |

| Finished frame dimensions (L x W x H) | L260-300mm W90-110 H20-50mm |

| Long tissue paper (W x L) | W50-100mm L460-540mm |

| Long tissue paper stacking height | L460-560mm |

| Greyboard thickness | 1-4mm |

| Greyboard length | W20-50mm L700-820mm |

| Greyboard stacking height | 530mm |

| Folding Size | 5-50mm |

| Precision | ±0.05mm |

| Speed | ≤25pcs/min |

| Motor Power | 25KW |

| Electric Heating Power | 12KW |

| Air Supply | 60L/min |

| Machine Weight | L6975mm×W5715mm×H1970mm |

| Machine Dimension | 6000kg |

1.The max and mini sizes of the covers are subjected to the size and the quality of the paper.

2.The speed of the machine depends on the sizes of the covers.

3.We don't provide air compressor.

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.