New Processed chromed glue roller makes the gluing evenly and thinly.

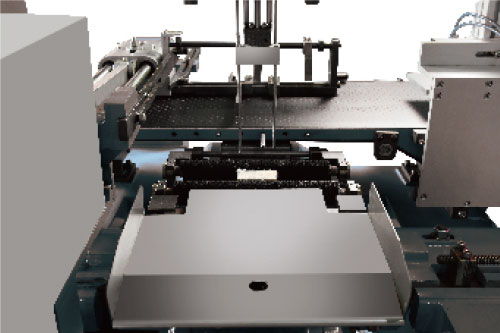

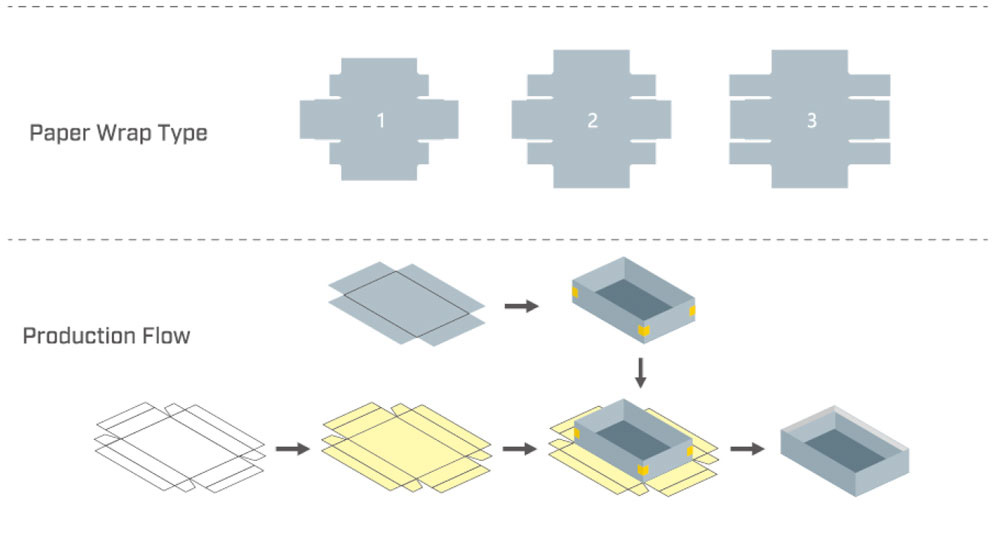

The PLC programmable controller, image positioning system, servo control system and touch screen human-machine interface are used to realize the one-time completion of automatic facial paper feeding, facial paper gluing, cardboard automatic conveying, cardboard forming and pasting, positioning and pasting, carton forming and other actions, effectively replacing manual production, and greatly improving the production efficiency and the quality of finished cartons.

≤35

boxs / min

It can be used to make high-grade and small size paper boxes such as mobile phone boxes, jewelry boxes, gift boxes, etc.

1.Full automatic feeder of paper.

2.Hot melt adhesive automatic circulation, mixing and gluing system (glue viscosity system can be selected).

3.The hot melt adhesive tape automatic conveying and slitting device can complete the corner pasting of the cardboard inner box at one time.

4.A vacuum suction fan is arranged below the conveyor belt to control the glued paper without relative deviation.

5.High definition image rectification and servo transmission are adopted for the coated paper and cardboard inner box, which can accurately position and fit.

6.The carton forming section automatically collects the carton to the forming section according to the carton conveying condition above the conveyor belt.

7.The continuous operation of the carton forming section includes box feeding, edging, ear folding and paper edge folding.

8.The whole machine adopts PLC control and touch screen human-machine interface to realize the automatic production process of one-time carton forming.

9.Automatic fault diagnosis alarm function.

New Processed chromed glue roller makes the gluing evenly and thinly.

Use environment-friendly tape to paste four corners, forming the box in one time withgood appearance.

HD camera positioning technology makes the operation easy and accurate.

Adopt mechanical gripper to deliver the box. lts adjustment is simple and fast.

Friendly-designed all icons control panel, easy to understand and operate.

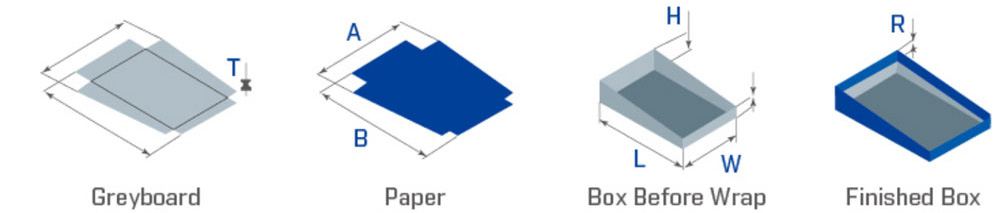

| Model | RB240 |

| Box Size (WxL) | Min. 45×45mm |

| Max. 160×240mm | |

| Paper Size (AxB) | Min. 80×110mm |

| Max. 305×450mm | |

| Box Height (H) | 12-80mm |

| Turn ln Depth (R) | 10-20mm |

| Cardboard Thickness (T) | 0.8-3mm |

| Paper Thickness | 80-300g/m |

| Precision | ±0.2mm |

| Speed | ≤35pcs/min |

| Motor Power | 8kw/380v 3phase |

| Electric Heating Power | 7kw |

| Air Supply | 20L/min 0.6Mpa |

| Machine Dimension | L430o×W3900×H2600mm |

| Machine Weight | 4000kg |

| Paper Wrap Type | 1 |

Main accessories

1.PLC system: OMRON

2.Transmission system: Taiwan Yintai YINTAI

3.Electrical components: SCHNEIDER

4.Photoelectric element: OMRON, Japan

5.Pneumatic components: Japan SMC

6.Frequency converter: SCHNEIDER, France

7.Servo system: OMRON

8.Touch screen: OMRON

9.Conveyor belt: HABASIT, Haberster, Switzerland

10.Main motor: Italy MGM

11.Bearing: Japan NSK

12.Vacuum pump: Becker

13.Gluing system: stainless steel chrome plated rubber roller and all copper gear pump

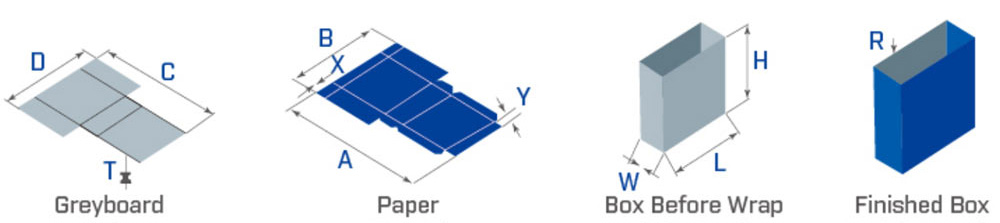

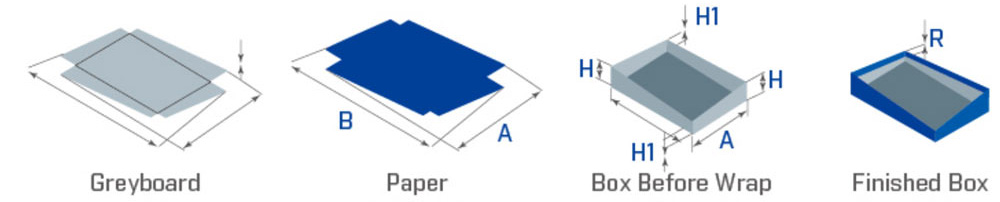

1.Size Range 0f Double-sided Folded Ear Cover Paper And Gray Plate

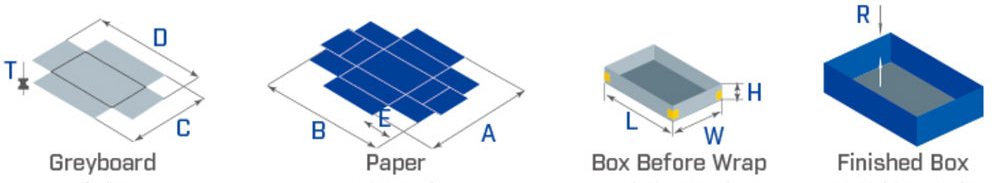

2.Size Range Of Cover Paper And Grey Board For Book Cover Boxes [T-type Boxes]

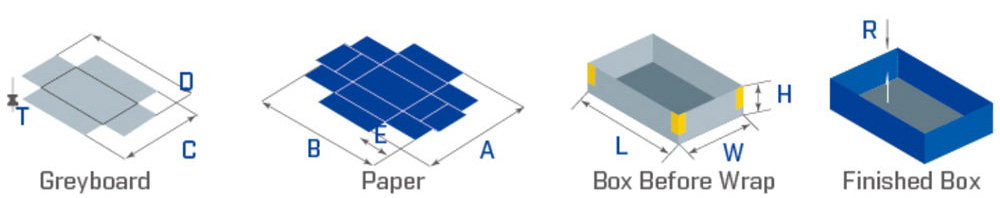

3.Size Range Of Butt-jointed Top And Bottom Cover Paper And Grey Board

4.Size Range Of Beveled Edge Cover Paper And Gray Plate

5.Size Range Of Diagonal Beveled Top And Bottom Cover Paper And Gray Plate

1.The Max.and Min. sizes of the boxes are subjected to the sizes and quality of the paper.

2.The speed of the machine depends on the sizes of the boxes.

3.We don't provide air compressor.

W+2H-4T

A(Min)

L+2H-4T≤D(Max)

B(Min)≤L+2H+2T+2R

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.