Cardboard Positioning

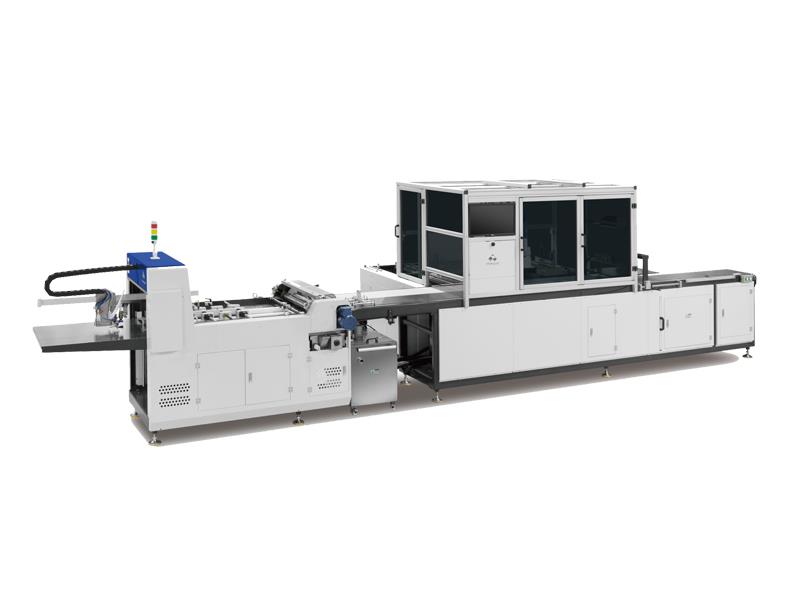

The paper carton erecting machine is an ideal choice to produce hamburger boxes, chips boxes, take away box, etc. It adopts micro-computer, PLC, servofeeding, alternating current frequency converter, the vacuum-sucking auto gluing, automatic paper tape counting, chain drive. Al of these main parts and electric control system adopts famous brand to guarantee steady working,precise positioning, smooth running, safety and relability operation.

Pls let us know if your box is not in blew list The paper rectifying device ensures that the paper is not offset after gluing.

<35

boxs / min

It can make more than 10 types of boxes.

Cardboard Positioning

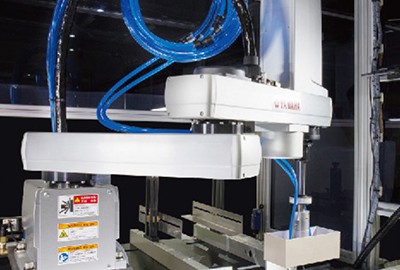

Box Positioning The first domestic three-camera positioning system.

| Model | CB450 | CB540 |

| Case Size[WxL] | Min:100x200mm Max:450x800mm | Min.100x200mm Max.540x800mm |

| Box Size[WxL] | Min.50x100mm Max.320x420mm | Min.50x100mm Max.320x420mm |

| Box Height[H] | 10-120mm | 10-120mm |

| Paper Size[WxL] | Min:100x200mm Max: 480x830mm | Min.100x200mm Max.570x1030mm |

| Paper Thickness | 100-300g/mz | 100-300g/m |

| Cardboard Thickness[T] | 1-3mm | 1-3mm |

| Precision | +0.1mm | +0.1mm |

| Speed | <35pcs/min | <35pcs/min |

| Motor power | 8kw/380v 3phase | 8kw/380v 3phase |

| Electric Heating Power | 12kw | 12kw |

| Air Supply | 10L/min 0.6Mpa | 10L/min 0.6Mpa |

| Machine Dimension | L6200xW2200xH2000mm | L7350xW3520xH2000mm |

| Machine Weight | 2000kg | 2200kg |

Main accessories:

PLC system : Japan Omron PLC system

Electrical components : France SCHENIDER

Pneumatic components : Japan SMC

Ultrasonic double paper test: German PEPPERL FUCHS

Conveyor belt: Switzerland HABASIT

Servo motor: Japan YASKAWA

Timing belt: German CONTIECH

Bearings: imported NSK bearings

Vacuum pump: Japan ORION

Manipulator: Japan YAMAHA

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.