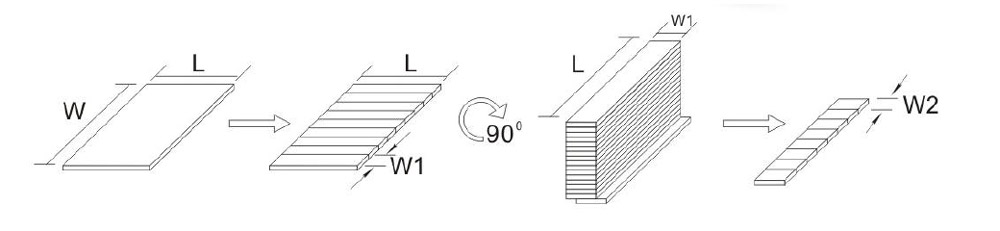

It is mainly used for cutting materials such as cardboard, industrial cardboard and grey cardboard, with high precision and fast production efficiency. It is an essential equipment for the production of hardcover book covers.

It is used to make hardcovers, notebook covers, desk calendars, hanging calendars, book-type boxes, files and rregular covers etc.

It Can automatically feed and glue paper, delivery and position cardboard,and fold four sides in one process; there are features of accurate and quick positioning, and beautiful finished products etc.

1. Large cardboard adopts manual propulsion, long cardboard adopts automatic feeding mode;

2. Servo propulsion feed, touch screen value setting, easy to adjust;

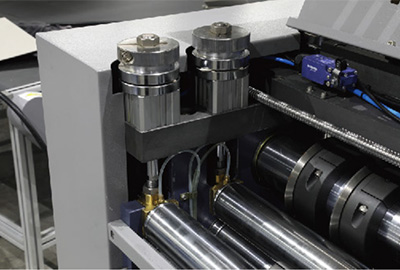

3. Pneumatic adjustment of press roll clearance, simple, convenient and fast operation;

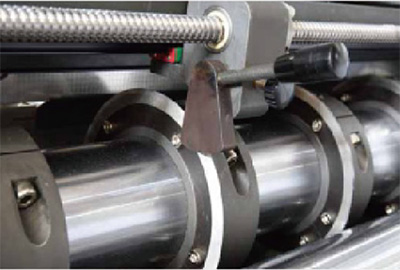

4. Digital adjustment of cutting knife spacing,save time and effort;

5. CE standard safety cover;

6. Centralized lubrication system;

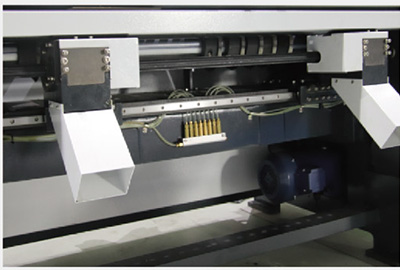

7. The new waste removal device can cut up the cardboard edge material and send it out of the machine through a small conveyor belt;

8. 2m receiving conveyor belt can be neatly stacked cut cardboard;

High efficiency: The KL1300A cardboard cutter machine uses advanced cutting tools and control systems, which enables it to cut cardboard quickly and accurately, improving production efficiency.

High automation: The KL1300A cardboard cutter machine has automatic feeding, cutting, and discharge functions, which can achieve a highly automated production process, reducing labor costs.

High cutting quality: The KL1300A cardboard cutter machine uses high-quality cutting tools and control systems, which can achieve high-precision cutting, ensuring cutting quality and dimensional accuracy.

Strong stability: The KL1300A cardboard cutter machine uses high-quality materials and stable structural design, which has a strong stability characteristic, allowing it to operate stably for a long time.

Simple operation: The KL1300A cardboard cutter machine adopts a user-friendly interface and simple and understandable operation process, making it easy for operators to use.

Wide application range: The KL1300A cardboard cutter machine can be used to cut various thicknesses of cardboard, card paper, grey board paper, etc., and is widely used in the packaging, printing, footwear, furniture, and other industries.

It adopts bottom drawing type non-stop feeder, which is suitable for small size material cutting.

Using alloy material round knife, durable,effectively reduce wear and improve cutting efficiency.

Pneumatic pressure adjustment, conve-nient and fast, reduce the technical personnel on the machine operation requirements.

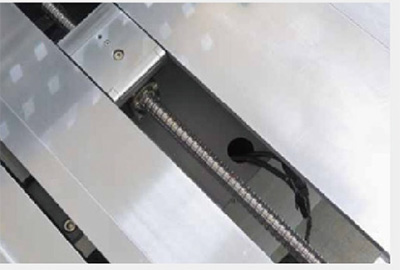

The feeder adopts servo motor and ball screw, which improves the accuracy and makes the adjustment easier.

Digital setting of knife spacing. according to the setting, the gauge automatically moves to the designated position, easy to adjust, no need to measure.

After the board is cut, the left and right wastes are automatically send to the crusher, and then conveyor belt send them out of machine, whichis simple and practical, and reduces the labor intensity

| Model | FD-KL1300A |

| Cardoard width | W<1300mm, L<1300mm W1=100-900mm, W2≥55mm |

| Cardboard thickness | 1-4mm |

| Speed | ≤60m/min |

| Cutting precision | ±0.1mm |

| Motor power | 4kw/380v 3phase |

| Air supply | 0.1L/min 0.6Mpa |

| Machine weight | 1300kg |

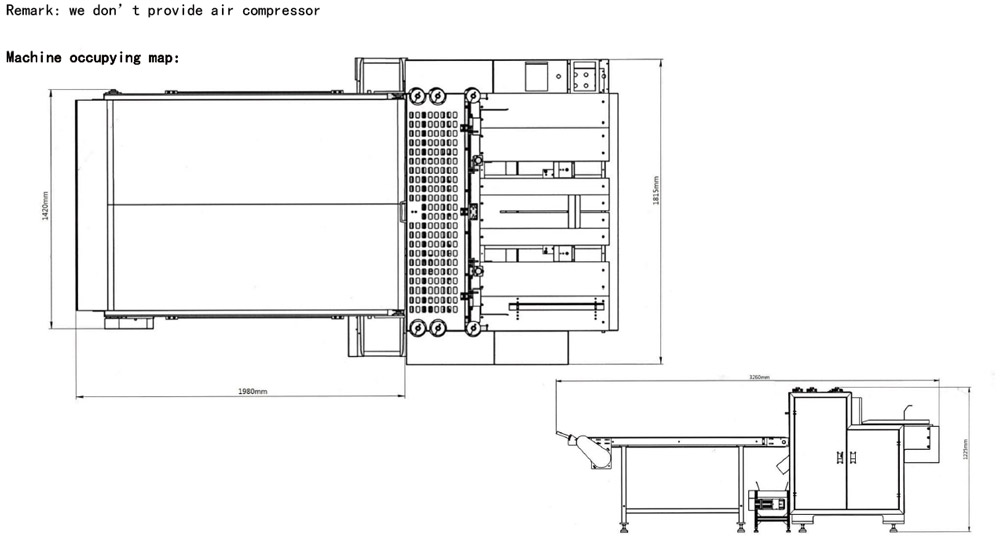

| Machine dimension | L3260×W1815×H1225mm |

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.