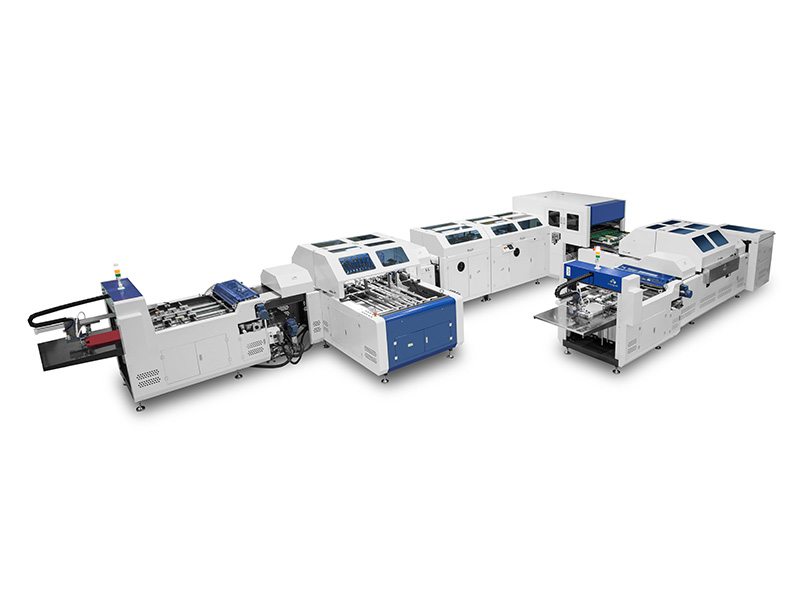

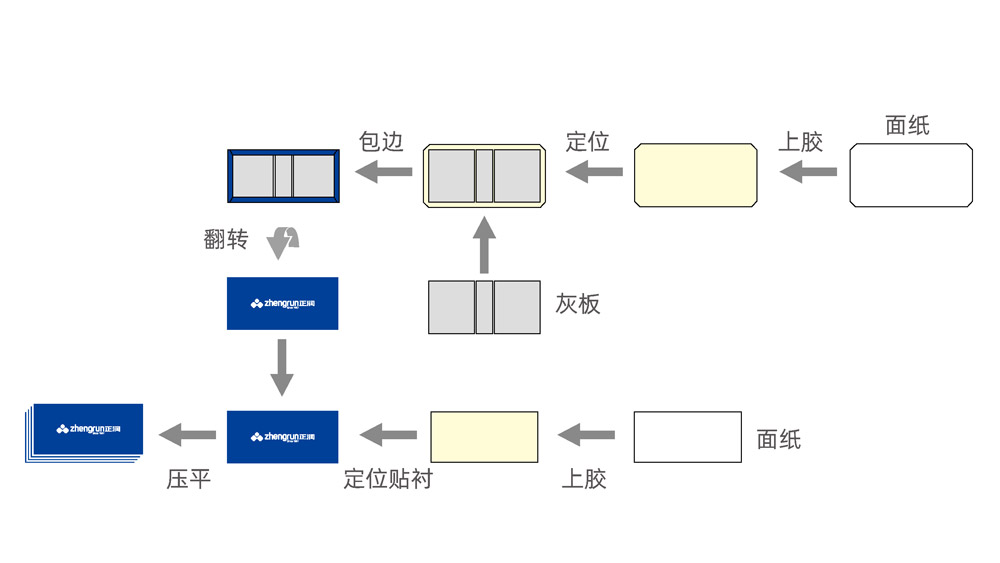

It Can automatically feed and glue paper, delivery and position cardboard, and fold four sides in one process; there are features of accurate and quick positioning, and beautiful finished products etc.

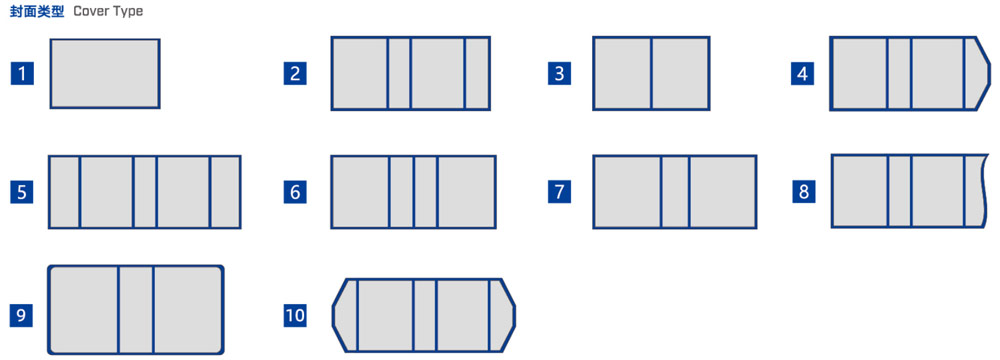

It is used to make hardcovers, notebook covers, desk calendars, hanging calendars, book-type boxes, files and rregular covers etc.

1. Automatically delivery outer paper, stacking height 520mm, with double sheet detector.

2. Automatically delivering for cardboards, Max.6pieces.

3. Hot melting glue circulation system viscosity meter(Optional)/Cold gluing circulation system with drying oven(Optional).

4. Position correction device, +/-0. 1mm.

5. Automatically folding and forming case four-edge. (Available to make Irregular shape cases).

6. Automatic turner to flip the semi finished cover to the stacker of lining machine.

7. Anti-scratch device to avoid the scratches during the delivery;(Optional).

8. Automatically delivery inner paper, stacking height 520mm, with double sheet detector.

9. Stacker with rubber rollers to flatten and collect the finished products.

10. Integrated cover is designed according to the European CE Standards,featuring in safety and humanity.

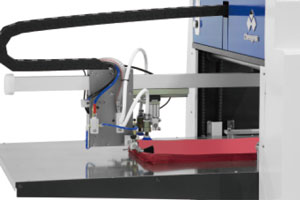

Full-pneumatic Feida: simple mechanism, convenient operation and accurate action.

Ultrasonic double-sheet paper detection can effectively prevent double-sheet paper and reduce waste products.

High-precision photoelectric positioning, photoelectric tracking and detection, servo correction to ensure positioning accuracy.

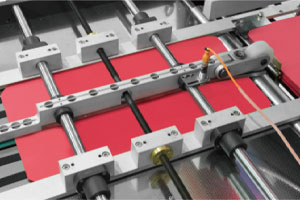

Trimming controlled by stepper motor, adjustable, faster and more accurate.

Liner down-suction device is used to down-suction and transport paperboard without stopping the machine, effectively preventing scratches on finished products.

The heavy roll flattening device can effectively remove bubbles and improve flatness with pressure groove function.

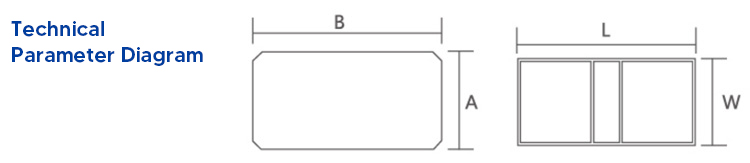

| Model | CMD540 |

| Paper Size (A×B) | Min.130×230mm Max.570×1030mm |

| Paper Thickness | 100~30og/m² |

| Cardboard Thickness | 1~4mm |

| Case Size | Min.10O×200mm Max.540×1000mm |

| Min.Spine Width (s) | 7mm |

| Folding Size | 10~18mm |

| cardboard Qty | 6pieces |

| Precision | ±0.1mm |

| Speed | ≤35sheets/min |

| Motor Power | 20kw/380v 3phase |

| Electric Heating Power | 24kw |

| Air Supply | 55L/min 0.6Mpa |

| Machine Weight | 6500kg |

| Machine Dimension | L12000×W4450×H1800mm |

1.The max and mini sizes of the covers are subjected to the size and the quality of the paper.

2.The speed of the machine depends on the sizes of the covers.

3.We don't provide air compressor.

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.