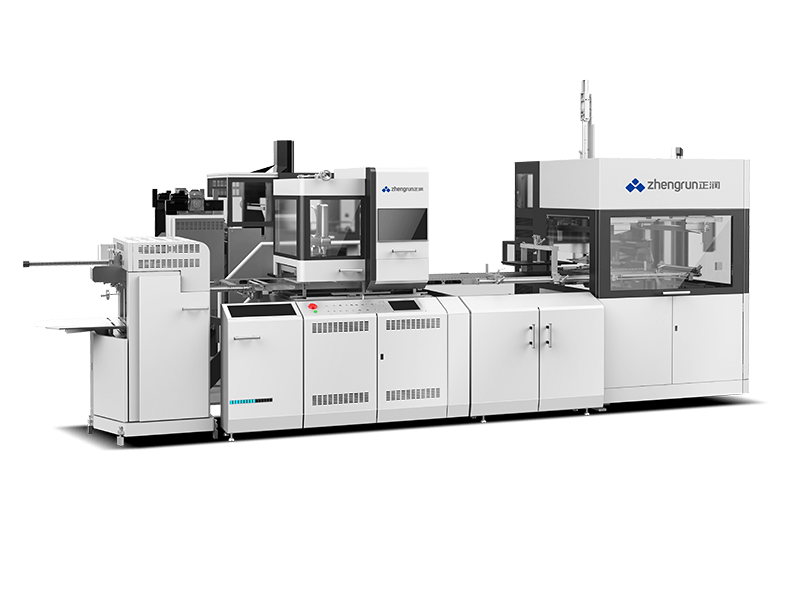

Automatic Rigid Box marker is a good equipment for making high-grade boxes which is featured by fne design, reliable performances and international advanced technologies. It employs PLC, photoelectric detector system, hydraulic rectifying system, HMI to automatically finish feeding and gluing paper, conveying cardboard, forming and gluing four angles of cardboard, positioning and forming box in one time, instead of manual production, greatly improving the production effciency and quality of rigid boxes.

It is applicable to make high-grade boxes for cell phones, shoes,cosmetics, shirts, moon cakes, liquors, cigarettes, teas, etc.

This fully automatic carton forming machine is the ideal equipment for producing high-end, high-quality cartons with lids and tops. It features a rational design, reliable performance, and world-class technology. It utilizes a PLC programmable controller, photoelectric tracking/image positioning system, pneumatic system, and touch-screen human-machine interface. It automatically feeds tissue paper, glues tissue paper, conveys cardboard, forms and tapes the corners, positions and fits the paperboard, and completes the carton forming process in one operation, effectively replacing manual labor and significantly improving production efficiency and the quality of finished cartons. It is suitable for producing high-end cartons for mobile phones, shoe boxes, cosmetics boxes, shirt boxes, moon cake boxes, wine boxes, cigarette boxes, tea boxes, and other high-end packaging.

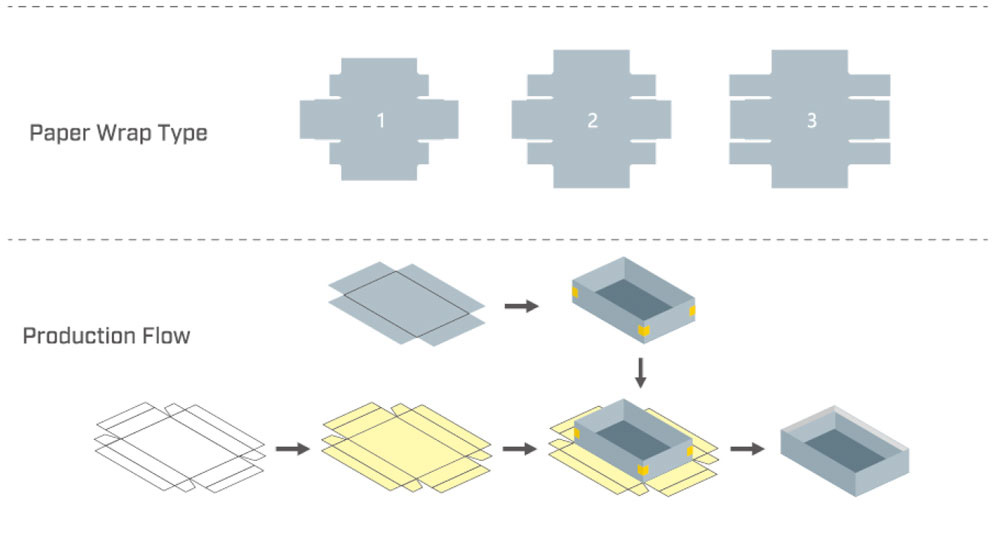

1) Full automatic feeder of paper.

2) Hot melt adhesive automatic circulation, mixing and gluing system (glue viscosity system can be selected).

3) The hot melt adhesive tape automatic conveying and sitting device can complete the corner pasting of the cardboard inner box at one time.

4) A vacuum suction fan is arranged below the conveyor belt to control the glued paper without relative deviation.

5)The hydraulic and pneumatic deviation correction device is adopted for the iner box of coated paper and paperboard, wich can accurately position and fit wih a fitting eror of ±0.3mm. With Yamaha YAMAHA manipulator image positioning,accuracy±0.1mm.

6) The carton forming section automatically collects the carton to the forming sectionaccording to the carton conveying condition above the conveyor belt.

7) The continuous operation of the carton forming section includes box feeding, edging, ear folding and paper edge folding.

8) The whole machine adopts PLC control, photoelectric tracking system and touch screen human-machine interface to realize the automatic production process of one-time carton forming.

9) Automatic fault diagnosis alarm function.

10) The new molding machine can store parameter settings and automatically adjust the machine.

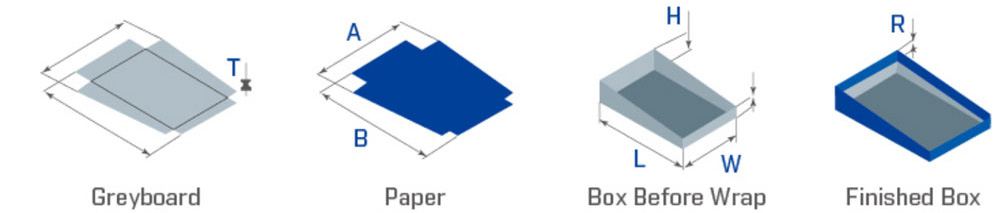

| Model | RB185 |

| Box Size[WxL] | Min. 50×100mm |

| Max. 400×600mm | |

| Paper Size[AxB] | Min. 95×180mm |

| Max. 610×850mm | |

| Box Height[H] | 10-185mm |

| Turn In Depth[R] | 10-100mm |

| Cardboard Thickness[T] | 0.8-3mm |

| Paper Thickness | 100-400g/m² |

| Precision | ±0.1mm |

| Speed | ≤30pcs/min |

| Motor Power | 20kw/380v 3phase |

| Electric Heating Power | 12kw |

| Air Supply | 50L/min 0.6Mpa |

| Machine Dimension | L7000×W5000×H3600mm |

| Machine Weight | 6800kg |

| Paper Wrap Type | 1/2/3 |

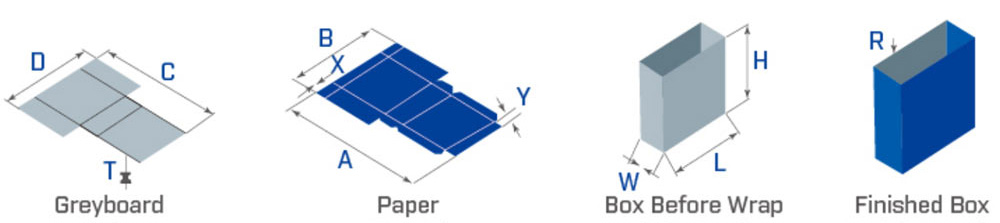

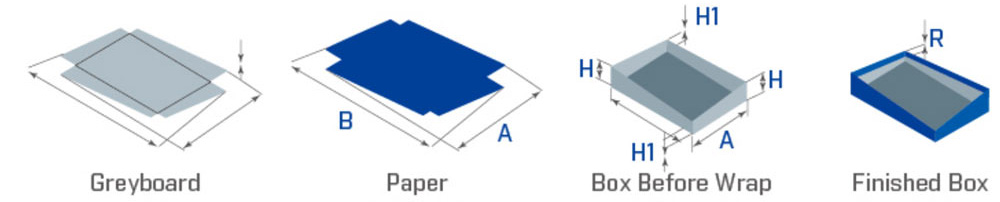

1.Size Range 0f Double-sided Folded Ear Cover Paper And Gray Plate

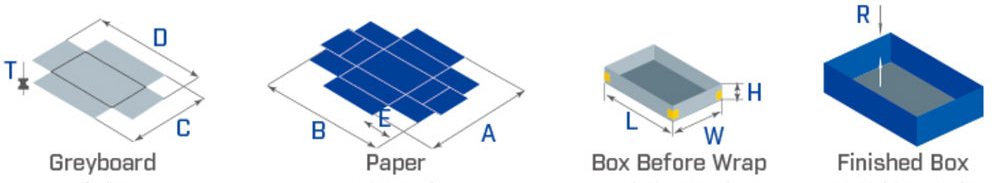

2.Size Range Of Cover Paper And Grey Board For Book Cover Boxes [T-type Boxes]

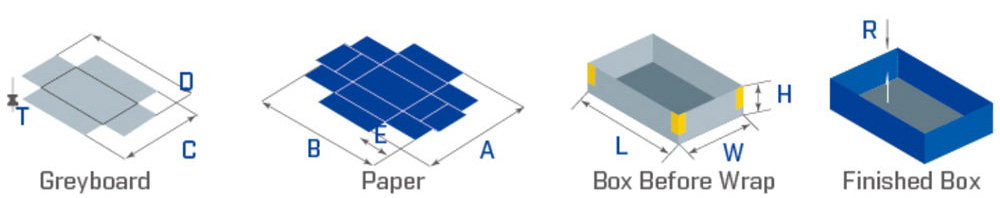

3.Size Range Of Butt-jointed Top And Bottom Cover Paper And Grey Board

4.Size Range Of Beveled Edge Cover Paper And Gray Plate

5.Size Range Of Diagonal Beveled Top And Bottom Cover Paper And Gray Plate

1.The Max. and Min. sizes of the boxes are subjected to the sizes and quality of the paper.

2.The speed of the machine depends on the sizes of the boxes.

3.We don't provide air compressor.

W+2H-4T≤C(Max)

A(Min)≤W+2H+2T+2R≤A(Max)

L+2H-4T≤D(Max)

B(Min)≤L+2H+2T+2R≤B(Max)

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.