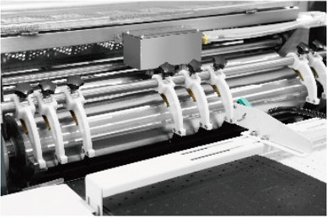

Patented rear suction paper feeder with independent servo control for paper feeding, simple and easy to maintain.

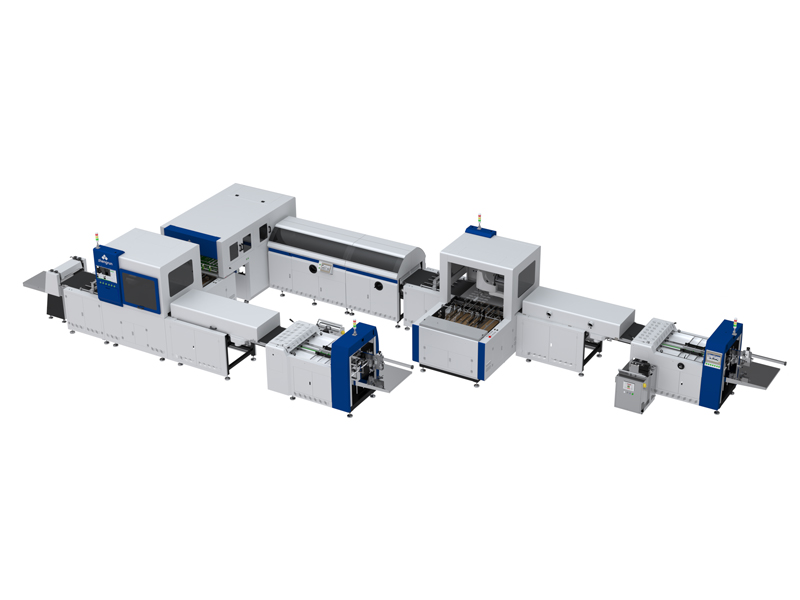

CBD600 Automatic Visual Positioning All-in-One Case Maker

The large-format, all-in-one solution for finished, lined hard covers. This machine combines case making and inner lining into one automatic process.

Features Visual Positioning (CCD) for high accuracy and One-key Adjustment for rapid setup.

Function: Produces a fully-lined cover in a single pass.

Max. Size: 580 x 1000 mm

Benefit: Saves space, labor, and time. Ideal for large-format jobs.

Applications: Perfect for large book covers, oversized folders, and calendars.

≤35

boxs / min

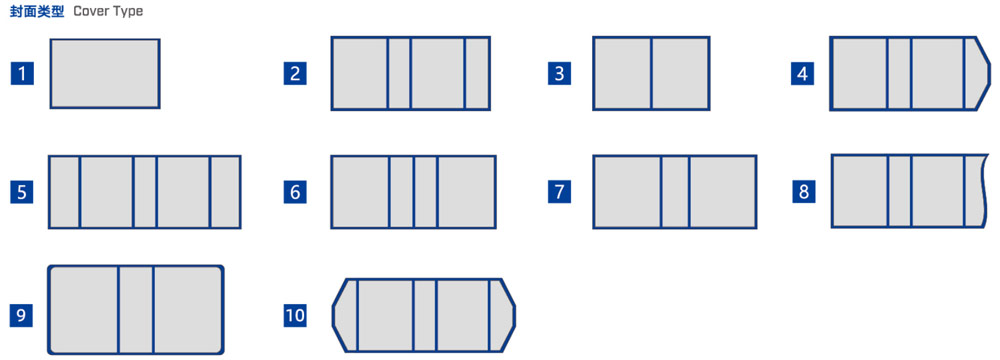

A complete, one-piece cover. For example, a finished dictionary hard cover (with the outside wrap and inside lining paper already attached); or a high-end folding game board.

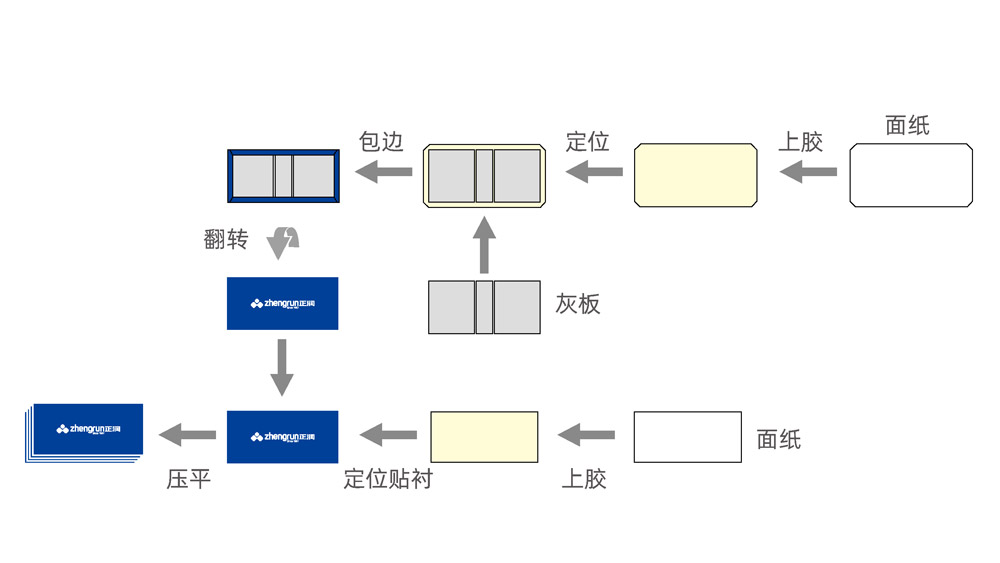

It can automatically feed and glue paper, delivery and position cardboard, and fold four sides in one process; there are features of accurate and quick positioning, and beautiful finished products etc. It is used to make hardcovers, notebook covers, desk calendars, hanging calendars, book-type boxes, fles and irregular covers etc.

Patented rear suction paper feeder with independent servo control for paper feeding, simple and easy to maintain.

Ultrasonic double-sheet paper detection can effectively prevent double-sheet paper and reduce waste products.

High-precision photoelectric positioning, photoelectric tracking and detection, servo correction to ensure positioning accuracy.

![Lining Suction Device [Optional]](https://meiguo-oss.oss-us-west-1.aliyuncs.com/zhengrun_new/upload/1c/202510/CBD450-Product-Advantage-4.jpg)

Liner down-suction device is used todown-suction and transport paperboard without stopping the machine, effectively preventing scratches on finished products.

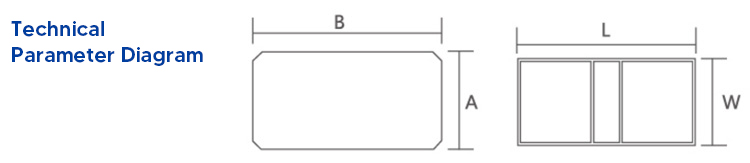

| Model | CBD600 |

| Paper Size[A×B] | Min. 130×230mm Max. 620×1030mm |

| Case Size[W×L] | Min. 100×200mm Max. 580×1000mm |

| Paper Thickness | 100~300g/m² |

| Cardboard Thickness | 1-4mm |

| Min.Spine Width[S] | 7mm |

| Folding Size | 10-18mm |

| Cardboard Qty | 6pieces |

| Precision | ±0.05mm |

| Speed | ≤35sheets/min |

| Motor Power | 20kw/380v 3phase |

| Electric Heating Power | 24kw |

| Air Supply | 55L/min 0.6Mpa |

| Machine Weight | 6500kg |

| Machine Dimension | L1400×W4400×H2000mm |

| Paper Wrap Type | 1/2/3/4/5/6/7/8 |

1.The max and mini sizes of the covers are subjected to the size and the quality of the paper.

2.The speed of the machine depends on the sizes of the covers.

3.We don't provide air compressor.

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.