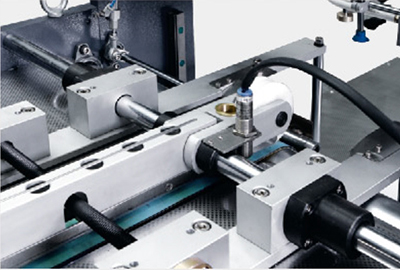

The ultrasonic double paper detector ensures the machine running and reduces the waste.

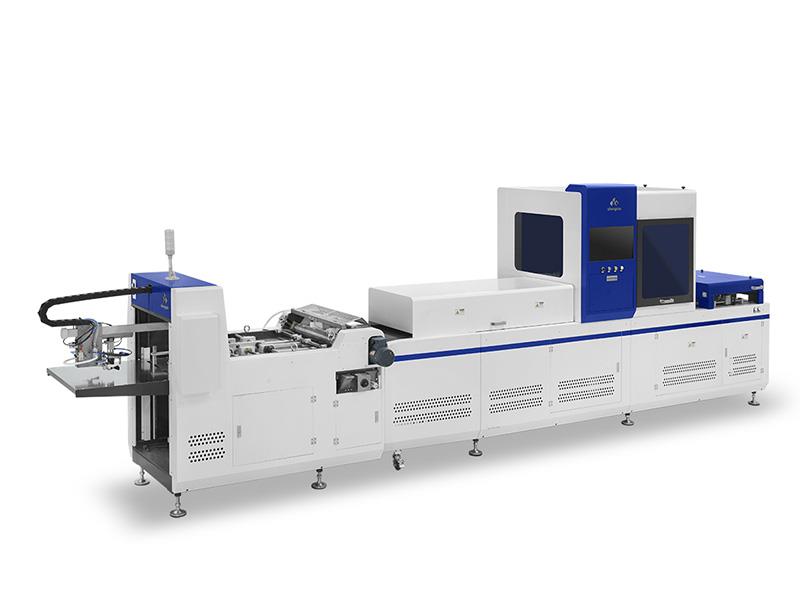

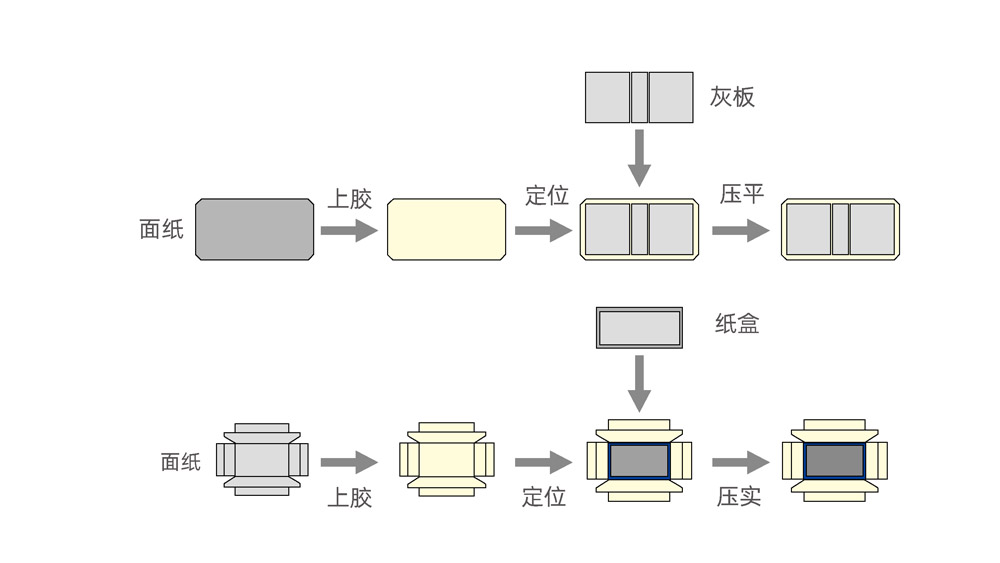

It Can automatically feed and glue paper, delivery and position cardboard,and fold four sides in one process, there are features of accurate and quick positioning, and beautiful finished products etc.

≤35

boxs / min

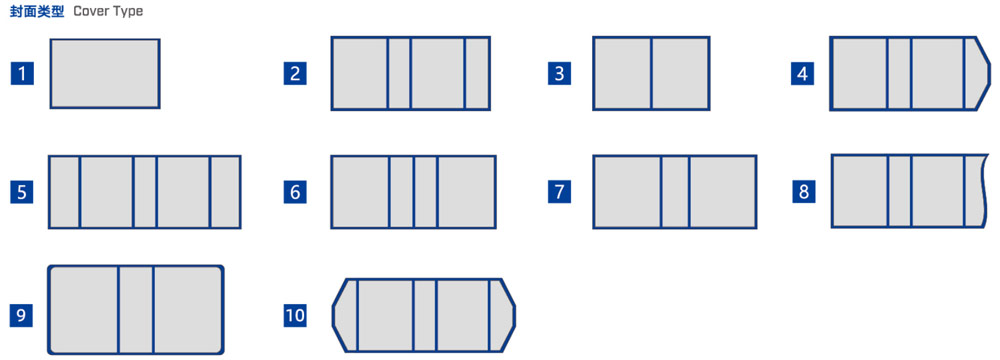

It is used to make hardcovers, notebook covers, desk calendars, hanging calendars, book-type boxes, files and rregular covers etc.

It can automatically feed and glue paper, delivery and position cardboard, and fold four sides in one process; there are features of accurate and quick positioning, and beautiful finished products etc. It is used to make hardcovers, notebook covers, desk calendars, hanging calendars, book-type boxes, fles and irregular covers etc.

The ultrasonic double paper detector ensures the machine running and reduces the waste.

Photoelectric Tracking Detection, Servo Deviation Correction To Ensure Position-ing Accuracy.

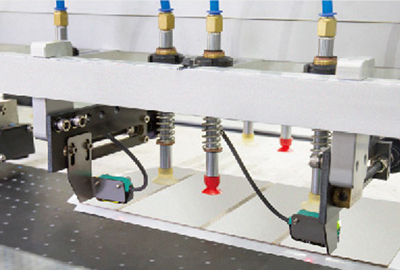

Non-stop downward suction type cardboard feeding device effciently ensures the products without scratches.

|

Model |

CB450 |

|

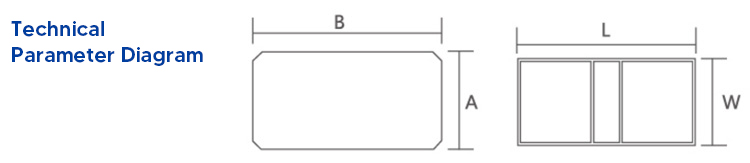

Paper Size (AxB) |

MIN:100x 180mm MAX: 480x 830mm |

|

Paper Thickness |

100~200g/m2 |

|

Cardboard Thickness[T] |

1-3mm |

|

Case Size[WxL] |

Min:70x1 50mm Max: 450x800mm |

|

Minimum Size of Center Strip |

10mm |

|

Maximum Number of Pieces Can Be Made |

5pieces |

|

Precision |

±0.1mm |

|

Speed |

≤35pcs/min |

|

Motor Power |

8kw/380v 3phase |

|

Electric Heating Power |

11kw |

|

Air Supply |

10L /min 0.6Mpa |

|

Machine Weight |

2000kg |

|

Machine Dimension |

L5450xW2241xH1900mm |

1.The max and mini sizes of the covers are subjected to the size and the quality of the paper.

2.The speed of the machine depends on the sizes of the covers.

3.We don't provide air compressor.

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.