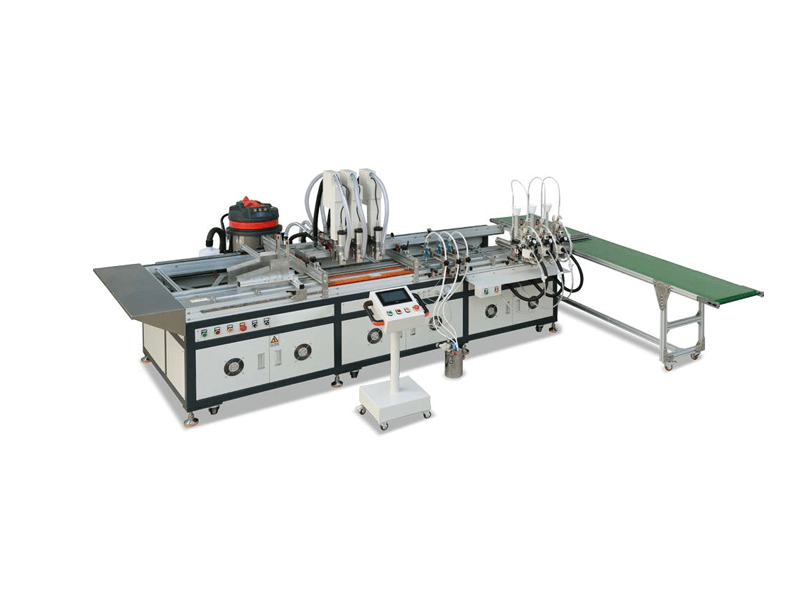

The machine is applied to make the book style rigid boxes. It has the functions of automatically feeding the material, drilling, gluing, sticking the magnets/iron discs.

40~50

boxs / min

In place of the hand working, it is efficient, stable and small footprint which is widely accepted by customers. In addition, it has the function of fault alarm and automatic shutdown, and sends out fault prompt information.

1. Auto non-stop feeder: It adopts the bottom drawn feeder. The material(cardboard/case) is fed from the bottom of stacker(Max.200mm).

2. Auto drilling: the depth of hole can be adjusted. And the waste of material is automatically removed and collected by vacuum cleaner. It avoids the problem of uneven hole by hand working .

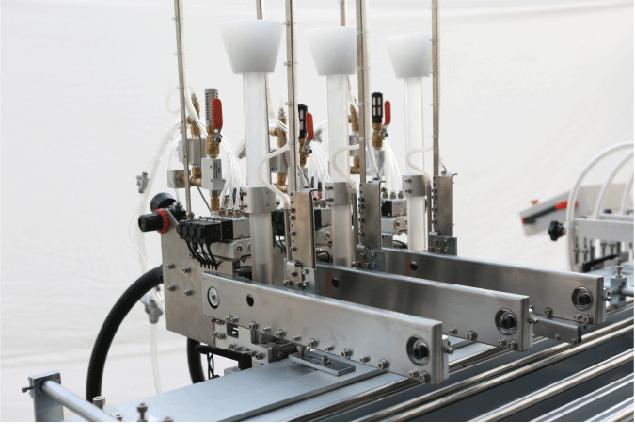

3. Auto gluing: The volume and position of gluing is adjustable according to the products, which efficiently solve the problem of glue squeeze -out and positioning. Iron disc has the optional device of Vibrating plate which can feed the discs automatically.

4. Auto sticking: It can stick 1-3pcs magnets/iron discs. The position, speed, pressure and program are adjustable.

| Model | ZR9060 |

| Paperboard size | Max. L1000×W500mm Min. L100×W40mm |

| Magnet diameter | 6-20mm |

| Product speed | 40-50pcs/min |

| Positioning accuracy | ±0.1mm |

| Card board thickness | 1-3mm |

| Pressure | 200-400mm |

| Stack height | 0.6-0.8Mpa |

| Power | 5kw/220V |

| Machine dimension | L3035×W1670×H1530mm |

| Weight | 750kg |

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.