New designed servo controlled paper feeder adopts post-sucking pre-pushing type to convey paper which efficiently avoids two pieces of papers entering into the machine.

According to the current market demand, our company will optimize the semi-automatic positioning line configuration of wine bags, and install Yamaha manipulator image positioning device imported from Japan, accurate positioning, improve the accuracy.

≤35

boxs / min

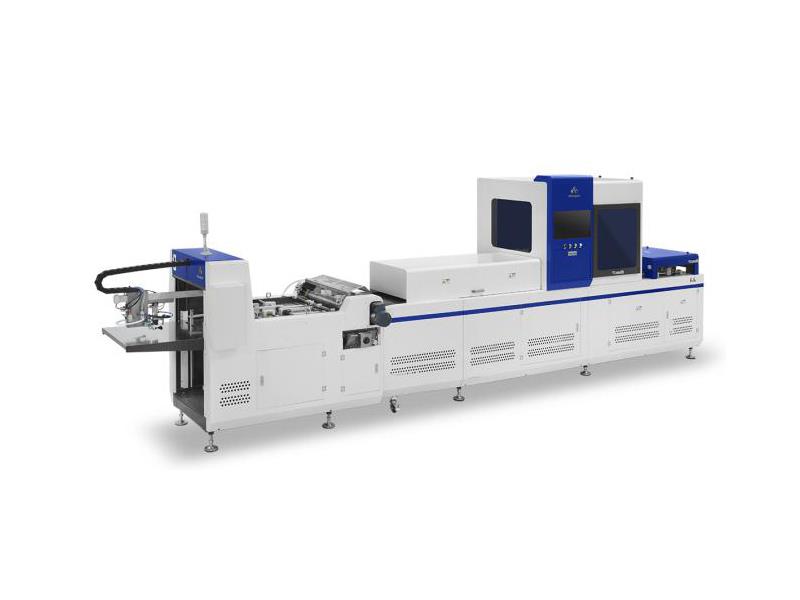

It has the characteristics of fast production speed, less labor, beautiful finished products, high positioning accuracy, can be widely used in the production of hardcover book cover, wine foreskin shell, cigarette foreskin shell, notebook, folder, desk calendar, wall calendar.

1. Full pneumatic head: simple structure, convenient operation, novel design, PLC control, accurate action (In China is the first, is my company's invention patent).

2. Cardboard conveying using the bottom extraction structure, in the case of machine without stopping, can be added at any time.

3.When the cardboard conveying is short, there is an automatic detection device (when sending several pieces of cardboard at the same time, less than one or several pieces of cardboard,the machine will stop the alarm).

4. cardboard/box conveyor with yamaha manipulator, dual cameras high-definition

5. image positioning, accuracy of +0.1 mm

New designed servo controlled paper feeder adopts post-sucking pre-pushing type to convey paper which efficiently avoids two pieces of papers entering into the machine.

Visual image positioning and mechanical arm ash feeding plate realize high-precision positioning.

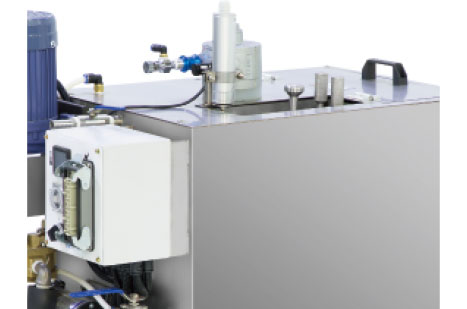

Auto glue viscosity meter efficiently adjusts the glue stickiness which ensures the quality of finished products.

| Model | JB540 |

| Paper Size (W×I) | MIN: 130×230mm |

| MAX: 570×830mm | |

| paper Thickness | 100~300g/m² |

| Cardboard Thickness (T) | 1~3mm |

| Finished Size | MIN: 100×200mm |

| MAX: 540X1000mm | |

| Spine Width (s) | 7mm |

| Maximum Number Of Slices | 6pieces |

| Precision | ±0.1mm |

| Speed | ≤35pcs/min |

| Motor Power | 8kw/380v 3phase |

| Electric Heating Power | 12kw |

| Air Supply | 10L/min 0.6Mpa |

| Machine Dimension | L6250×W2460×H2000 |

| Machine Weight | 2200kg |

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.