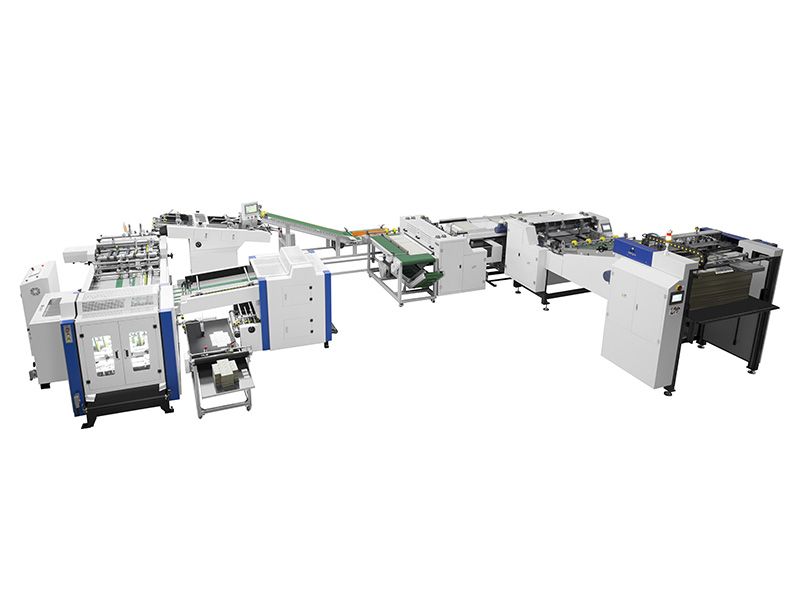

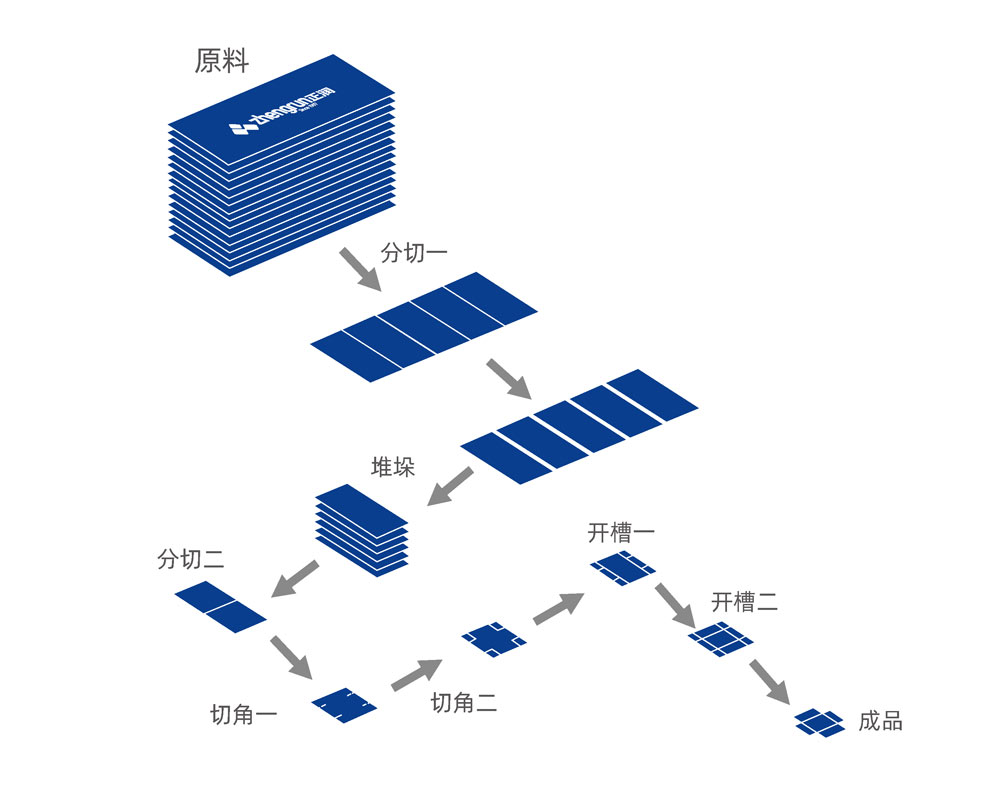

This machine is composed of three parts, the board cutting machine, the vertical and horizontal conveyor beltand the cutting machine, which can realize the cutting,slotting and corner cutting of the cardboard in one time,with high efficiency, quick and convenient, high accuracy of the finished product, which can greatly reduce the labour intensity of workers and the number of operators, and is a high-tech product with high cost performance.

Automatic feeding of large cardboard and long cardboard,low labour intensity for workers

1. Automatic feeding of large cardboard and long cardboard,low labour intensity for workers

2. 1.5 m top stack height;

3. Servo propulsion feeding, touch screen value setting,easy to adjust.

4. Slitting of cardboard to an accuracy of ± 0.1 mm;

5. Pneumatic adjustment of the pressure roller gap, simple,easy and fast to operate;

6. Digital adjustment of the cutter spacing, with high precision, saving time and effort in knife adjustment;

7. CE standard safety enclosure;

8. Centralised lubrication systems;

9. Equipped with a waste removal device to shred the cardboard edges and send them out of the machine via a small conveyor belt;

10. High degree of automation with two machines fully linked and a slitter at the back that can run automatically;

11. The middle feeder is motor-driven in both vertical and horizontal directions to adjust the position with precision and effort.

12. This machine has a number of patents such as servo-driven paper feeding mechanism and automatic knife adjustment device.

13. Touch screen human-machine interface, slitting sheet size and processing quantity can be preset.

Non-stop feeder with bottom feed, suitable for slitting small cardboard sizes

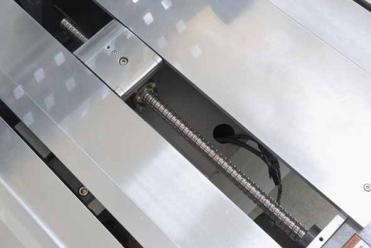

Material pushing head with servo motor with ball screw feed for increased precision and easier adjustment

The use of alloy material round knives, durable,effective in reducing wear and tear and improving slitting efficiency

Digital setting of the tool spacing, according to the setting, the leaning gauge automatically moves to the specified position for easy adjustment, without the need for additional caliper measurements

New CE standard enclosure for safer operation

After the large plate is cut, the waste material will automatically go into the shredder, and then the conveyor belt will send out the machine to reduce the labor intensity

Pneumatic pressure regulation, which is easy and quick and reduces the requirement for technicians to operate the machine

Good human-machine interface, simple to use; with counting and alarm functions

| Model | KX650SD |

| Large Cardboard Size | Min. 620×620mm Max. 1100×1260mm |

| Paperboard Slitting Finished Size | Min. 55×140mm Max. 520×1100mm |

| Slotted Finished Size | Min. 120×120mm Max. 550×600mm |

| Paperboard Thickness | 1.5-3.5mm |

| Stack Height | 1500mm |

| Cutting Accuracy | ±0.1mm |

| Cutting Speed [Open Large Boards] | ≤40pcs/min[300×300mm] |

| Running Speed | ≤120pcs/min[300×300mm] |

| Slotting Angle | 90°-130° |

| Accuracy Of Slot Spacing | ±0.1mm |

| Range of cut line lengths | 15-120mm |

| Cutting the line too far | ≤2mm |

| Number of grooved strips in the first course | 8 grooves |

| Number of grooved strips in second course | 4 grooves |

| Total power | 22.2kw/380v 3phase |

| Air supply requirements | 2L/min 0.6Mpa |

| Machine weight | 10000kg |

| Machine size | L10967×W5674×H1900mm |

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.