Double Feta feeder for more stable and reliable tissues.

Automatic box forming machine is the best equipment for making high-grade high-grade box with reasonable design, reliableperformance and the same technical level in the world.

≤56/≤30

boxs / min

Can be used tomake mobile phone box, shoe box, cosmetics box, shirt box, mooncake box, wine box, cigarette box

Tea box and other high-grade paper box packaging

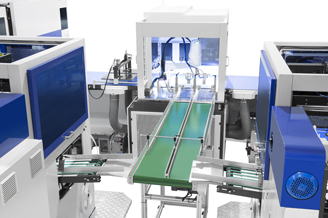

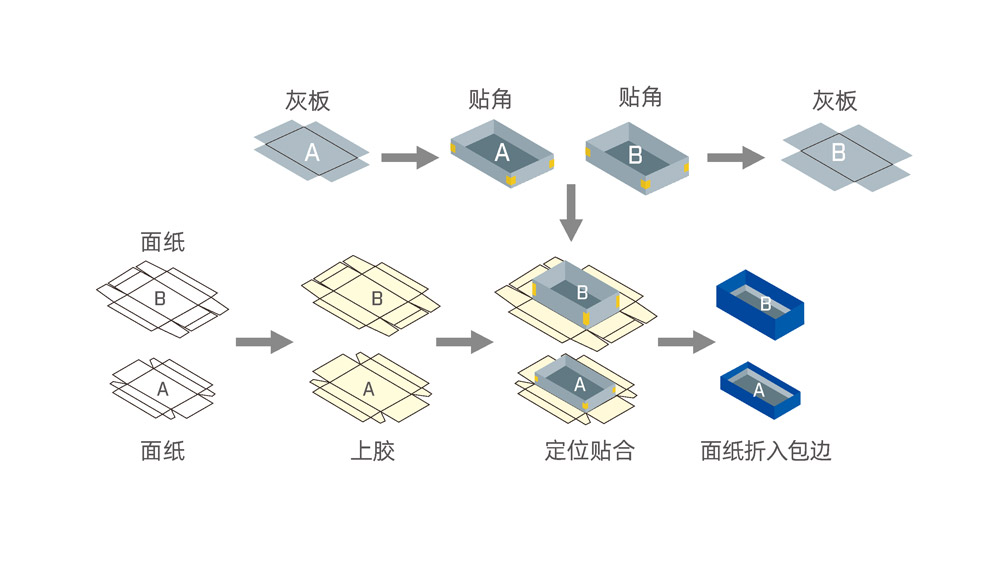

This fully automatic carton forming machine is the ideal equipment for producing high-end, high-quality cartons with lids and tops. It features a rational design, reliable performance, and world-class technology. It utilizes a PLC programmable controller, photoelectric tracking/image positioning system, pneumatic system, and touch-screen human-machine interface. It automatically feeds tissue paper, glues tissue paper, conveys cardboard, forms and tapes the corners, positions and fits the paperboard, and completes the carton forming process in one operation, effectively replacing manual labor and significantly improving production efficiency and the quality of finished cartons. It is suitable for producing high-end cartons for mobile phones, shoe boxes, cosmetics boxes, shirt boxes, moon cake boxes, wine boxes, cigarette boxes, tea boxes, and other high-end packaging.

PLC system: YASKAWA PLC system,Japan

Transmission system: IGUS,Germany

Electrical components: SCHNEIDER.France

Photoelectric components: Sicker, Germany

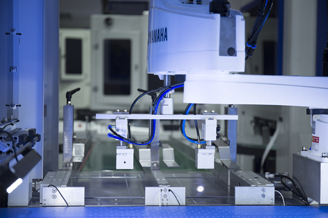

Positioning system: YAMAHA, Japan

Pneumatic components: SMC,Japan

Inverter: SCHNEIDER, France

Servo motor: YASKAWA, Japan

Stepper motor: Yamasawa SAMSR

Corner pasting machine control system: INOVANCE. China

Touch screen:PRO-FACEJapan

Conveyor belt: HABASIT, Switzerland

Vacuum pump: BECKER, Germany

Bearing: NSK/lKO bearing imported from Japan

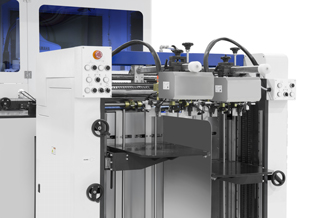

Double Feta feeder for more stable and reliable tissues.

Original imported robot, double-station suction cassette, fast and efficient.

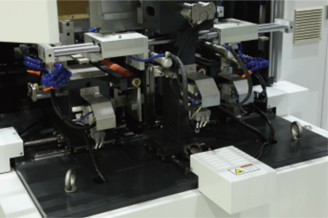

The servo control molding pressure is large, which can be comparable to the bubble pressing effect.

Dual access, dual corner fitting for efficient production.

|

Model |

RB380 SK Double Out Box Mode |

RB380 SK Single Out Box Mode |

|

Paper Size[AxB] |

Min. 70×120mm |

Min. 70×120mm |

|

Max. 410×630mm |

Max. 510×630mm |

|

|

Box Size[WxL] |

Min. 30×60mm |

Min. 30×60mm |

|

Max. 240×380mm |

Max. 260×380mm |

|

|

Box Height[H] |

10-140mm |

10-140mm |

|

Turn In Depth[R] |

10-100mm |

10-100mm |

|

Folded ear size |

10-100mm |

10-100mm |

|

Cardboard Thickness[T] |

0.8~3mm |

0.8~3mm |

|

Paper Thickness |

100-400g/m² |

100-400g/m² |

|

Paper Stacking Height |

750mm |

750mm |

|

Gray board stacking height |

1000mm |

1000mm |

|

Precision |

±0.05 mm |

±0.05mm |

|

Speed |

≤60pcs/min |

≤45pcs/min |

|

Motor Power |

28kw/380v 3phase |

28kw/380v 3phase |

|

Electric Heating Power |

12kw |

12kw |

|

Air Supply |

70L/min 0.6Mpa |

50L/min 0.6Mpa |

|

Machine Dimension |

L7600×W7800×H3300mm |

L7600×W7800×H3300mm |

|

Machine Weight |

6000kg |

6000kg |

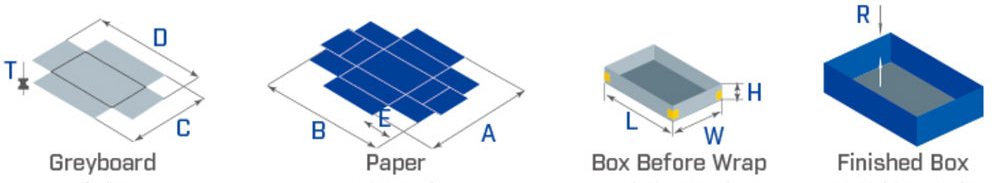

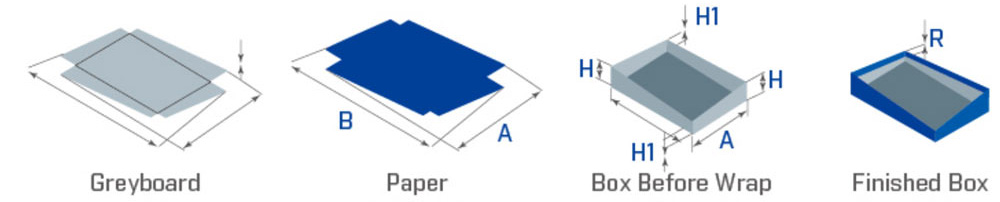

1.Size Range 0f Double-sided Folded Ear Cover Paper And Gray Plate

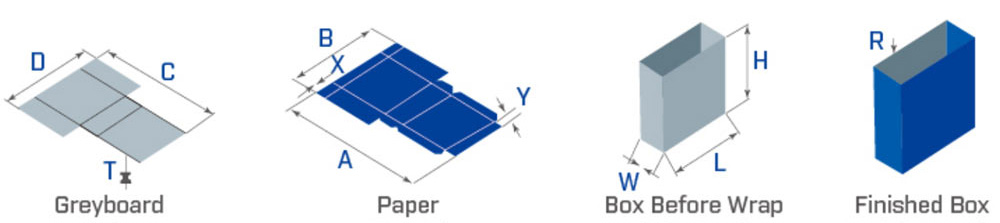

2.Size Range Of Cover Paper And Grey Board For Book Cover Boxes [T-type Boxes]

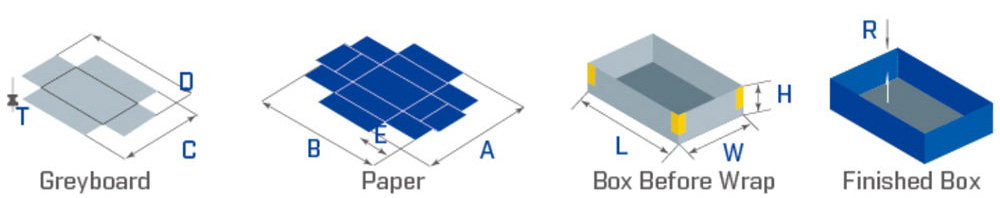

3.Size Range Of Butt-jointed Top And Bottom Cover Paper And Grey Board

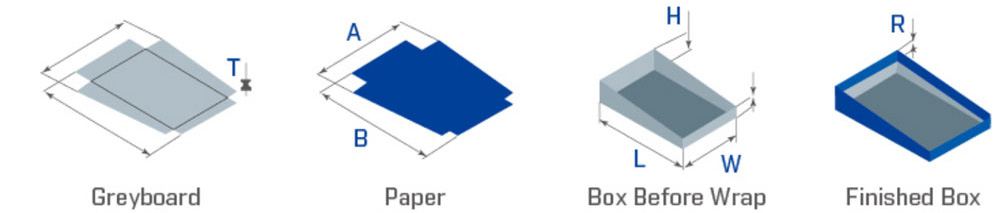

4.Size Range Of Beveled Edge Cover Paper And Gray Plate

5.Size Range Of Diagonal Beveled Top And Bottom Cover Paper And Gray Plate

1.The Max. and Min. sizes of the boxes are subjected to the sizes and quality of the paper.

2.The speed of the machine depends on the sizes of the boxes.

3.We don't provide air compressor.

W+2H-4T≤C(Max)

A(Min)≤W+2H+2T+2R≤A(Max)

L+2H-4T≤D(Max)

B(Min)≤L+2H+2T+2R≤B(Max)

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.